Making delicious food is a need for starting a panipuri-making business. The key to this business is knowing and excelling in the technique for making crispy, hollow puris and making tasty chutneys and drinks that are ultimately very refreshing.

Each Panipuri is filled to the brim with mouthwatering flavours thanks to careful attention to detail in the creation of a range of flavours, from spicy to sour and sweet.

1. Top 4 Pani Puri machine

- Dough Kneader Machine

The Panipuri-making industry totally and majorly depends on the dough kneader machine since it makes it easier for the seller to prepare the dough, which is most important and key component in the Panipuri shells.

Its main objective is properly and evenly combine and knead the dough to the required portion and evenly so that it can moulded into the proper panipuri.

The Panipuri dough materials, including flour, water, and other additions, are fed into the dough kneader machine for use. And then all the ingredients are combined and kneaded, along with consistent water amount to retain hydration and make it hydrated and to provide enough gluten formation.

This machine saves the lot of time of the worker, as this kneading is very tough part and time and energy consuming too.

When opposed to hand kneading, the machine’s architecture guarantees that the dough is fully worked. Additionally, the regular kneading procedure helps to ensure that the Panipuri shells are uniform and of high quality.

The dough kneader machine’s main benefits are efficiency and accuracy. The productivity of the Panipuri-making process is increased as a result of a large reduction in the physical labour and time required to knead dough. Through the provision of a regulated environment for dough preparation, this automated procedure also encourages cleanliness and safety.

The resulting well-kneaded dough is the base of the uniformly crisp and delicious Panipuri shells and provides taste and boosting the overall success of the Panipuri-making industry.

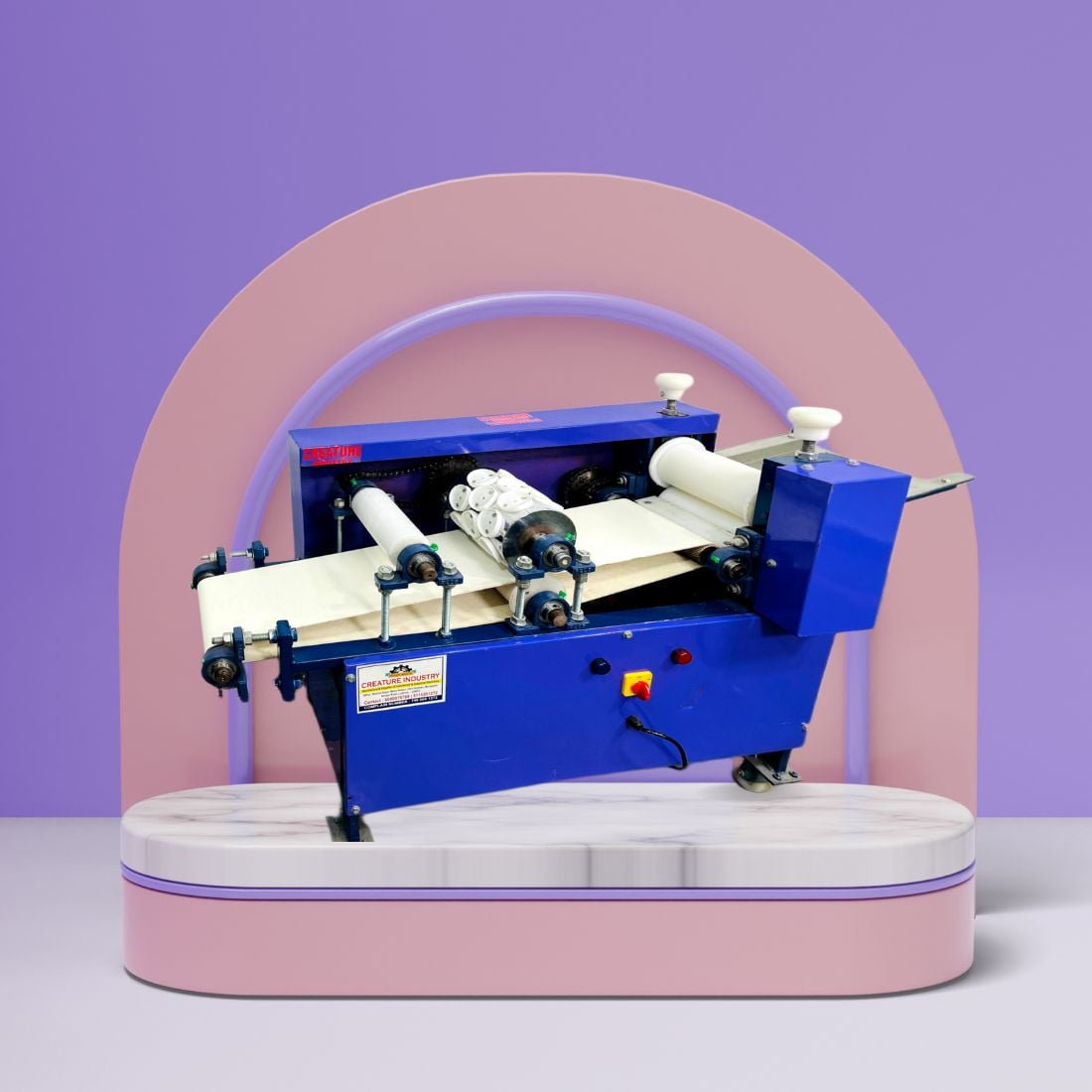

2. Dough Sheeter Machine

The dough sheeter machine is another important tool which is a part of a Panipuri making industry. This tool is a very helpful in making the dough flatten and shape the dough into thin sheets.

Now the thin sheets are ready to be fried into a panipuri. The main objective of this machine is to automatically flatten the dough and see the consistency and the uniformity of the this dough. This machine also helps to make the shells of panipuri to be evenly thicken and of same size.

Read also: Namkeen Packing Machine: 5 Most Important Namkeen Machine

3. Panipuri Machine

Panipuri Machine is the next equipment of this Panipuri manufacturing industry. This machine is mainly responsible for cutting the rolled dough into a tiny and circular form that a commonly known as Panipuri shells.

The main goal of panipuri machine is to automate the cutting to make sure that every shell is of equal size and this uniformly prepared, panipuri machine cuts the dough into tiny round form that is more evenly than any human can cut that.

Therefore this machine is very flexible and can meet our requirements this means that it is used to cut many shells at the time therefore it reduces the work of human labour. Panipuri machine is important in Panipuri manufacturing industry and it also guarantees the even and consistent and product.

4. Electric Fryer Machine

The electric fryer, which was made particularly for frying the cut dough pieces into crispy Panipuri shells, is a crucial part of the Panipuri-making industry. Its main objective is to efficiently and consistently fry the prepared dough in order to produce the required Panipuri-like texture and flavour.

The cut dough pieces are placed into the hot oil once the electric fryer has heated the oil to the proper frying temperature. The device guarantees evenly crispy Panipuri shells by keeping a steady temperature and controlling the frying duration. To produce a high-quality finished product while maximising energy use and preserving safety, the frying process must be automated.

The electric fryer’s main benefits are efficiency and uniformity. It decreases the amount of physical labour and frying time needed, therefore this enables increased output and fulfil the consumer demand.

Along with this these machine also supports business by providing a regulated and sanitary atmosphere for frying, the controlled frying process improves the hygienic elements of Panipuri manufacturing.

Conclusion

In conclusion, the dough kneader, dough sheeter, panipuri cutter, and electric fryer are crucial equipment for a panipuri-making enterprise and are the foundation of effective production. They provide consistency and quality by streamlining the whole process, from making the dough to creating the crispy shell. Together, these devices increase output, uphold cleanliness, and provide the genuine flavour and texture necessary for a Panipuri business to succeed.

Connect us on IndiaMart: Creature Industry

FAQ

-

1. What does employing an electric fryer in a Panipuri-making operation mean?

An electric fryer makes sure that the dough is fried uniformly and effectively, producing crispy Panipuri shells. By maintaining constant frying temperatures, it optimises the frying process while boosting taste and texture.

-

2. Can the panipuri machine be modified to produce shells of varied sizes?

The panipuri machine may, in fact, be adjusted to accommodate varying shell sizes for various Panipuri varieties and designs.

-

3. How can a dough mixer enhance the Panipuri manufacturing process?

By effectively kneading the dough, a dough kneader machine saves time and labour. It guarantees a homogeneous, smooth dough consistency, which is essential for making flawless Panipuri shells.

-

4. Can small-scale Panipuri enterprises use these machines?

It’s true that these machines come in a range of capacities, making them appropriate for both small- and large-scale Panipuri manufacturing. This versatility allows them to be tailored to different company requirements and operational sizes.

English

English

Dear creatureindustry.com administrator, Your posts are always well-referenced and credible.