Namkeen packing machine was made to solve the purpose of packaging the namkeens which is the last step in the whole namkeen making factory. These machines make packaging simpler more effective and way more hygienic than the earlier used old traditional method. These namkeen packing machines have better ability to pack, weigh the product equally, and distribute them in different packets.

This machine can handle variety of packing materials such as we can have plastic packaging, paper packaging etc. These namkeen packing machines have particular weighing system that weighs and distribute the exact amount of namkeen into each package. Therefore, this system also reduces namkeen waste by accurately dividing and packing in different packets. Namkeen packing machines also provide namkeen packets to intact freshness and avoid contamination.

Namkeen packing machines packs the packet and then fill them required amount of namkeen, and finally sealed and this freshness that is maintained inside the packages. Another advantage that these packaging machines provides are speed, this means these machines can pack more packets at the given time, so if someone is doing this business at large scale they can easily fulfill the needs of the business as well as the need of market.

When items are packed by these machines they are packed and sealed properly the particular branding presents the product to consumers very effective and attractive way this attracts more consumers and makes them permanent consumers of our products. Therefore these machines are also the important part of the whole Savory industry as these are the one that gives a final and refreshing touch to the namkeens.

There are many fields where one can try one’s luck and grow in business. One such blooming business is savory snacks that are namkeen. The cost of production, such as material sourcing, production expenses, and marketing costs, affects the profit margin in the Namkeen producing industry.

To set up a proper Namkeen packing business one requires these 5 machines, which are mentioned below –

- Besan Mixing Machine

- Farsan Machine

- Batch Fryer Machine

- Oil Dryer Machine

- Namkeen Masala Mixer

1. Besan Mixing Machine

This is one of the tool that is required in making Namkeen (Indian savory snacks), the besan mixing machine is very important during the early stages of production which is the stage at which one start to produce the product.

Its primary purpose is to blend and combine besan, a kind of gram flour, with various other required ingredients to create the fundamental Namkeen mixture.

By ensuring that components are spread equally, this gadget contributes to the final product having the right flavour, texture, and quality.

While in operation, the besan mixing machine combines besan with other ingredients in accordance with the pre-determined formula for the selected variety of Namkeen.

The machine’s design allows for efficient mixing, guaranteeing uniformity in flavour and texture throughout every batch. Proper mixing is crucial to achieving the various flavour profiles and ensuring that the flavour is consistent throughout the Namkeen.

The besan mixing machine’s main features are consistency and efficiency. It greatly minimizes the physical labor and time necessary for proper mixing, hence boosting output and raising productivity levels. By creating a controlled atmosphere for the mixing process and reducing human interaction with the mixture, the machine also improves cleanliness and safety.

The besan mixing machine ultimately simplifies the first phase of Namkeen production, establishing the groundwork for the succeeding procedures that turn the mixture into the mouthwatering array of Namkeen snacks that consumers enjoy. Its importance in producing a consistent and better product in the Namkeen manufacturing industry cannot be emphasized.

2. Farsan Machine

The Farsan machine, which specializes in the shaping and cutting of the Namkeen mixture to generate the particular forms and textures associated with various varieties of Namkeen snacks, is a crucial part of the Namkeen-making industry. Its main function is to extrude the combined dough or mixture via certain nozzles in order to produce particular forms, sizes, and patterns that correspond to the required properties of the finished product.

Depending on the specifications of the recipe, the farsan machine works by taking the Namkeen mixture and mechanically or automatically forming it into different shapes like strings, pellets, or sheets.

A variety of Namkeen snacks with distinctive textures and looks may be produced using the machine’s interchangeable nozzles, which provide versatility in shape.

The farsan machine makes a substantial contribution to the production process’ efficiency and standardization. It eliminates manual labor, saves time, and guarantees uniformity in the forms and sizes of the Namkeen products by automating the shaping and cutting procedures. The finished treats’ quality and marketability depend on this constancy.

Furthermore, by offering a regulated and sanitary environment for the shaping process, the farsan machine improves the hygienic elements of Namkeen manufacture.

3. Batch Fryer Machine

The batch fryer machine, which is primarily made for the frying stage of production, is an essential tool in the Namkeen manufacturing industry. Its major function is to completely submerge the formed Namkeen pieces in hot oil, producing the preferred crispy texture and flavor while preserving the snack’s quality. This equipment works in batches, giving the frying process complete control.

The batch fryer machine makes sure that the Namkeen pieces are consistently cooked to perfection during operation by maintaining a constant temperature and carefully monitoring the frying duration.

The regulated frying procedure is essential for improving the Namkeen’s flavor, texture, and appearance and fulfilling consumer demands for high-quality food.

Read also: Masala Packing Machine: Start Masala Making Business by Using 5 Machines

The batch fryer machine increases frying efficiency by maximizing oil utilization and reducing waste. By effectively regulating the frying process and minimizing any possible oil leaks, it helps to maintain a clean and safe atmosphere. In the end, this machine makes a substantial contribution to the entire manufacturing of premium Namkeen snacks, satisfying customer demand for savory and crispy delicacies.

4. Oil Dryer Machine

An essential tool for the Namkeen manufacturing process, the oil drier machine is used for the vital post-frying stage. Its main function is to remove extra oil from newly cooked Namkeen, which is essential for improving the snack’s flavor, texture, and shelf life. The equipment efficiently removes excess oil using processes like centrifugation or other ways, ensuring that the Namkeen maintains its desired crunchiness and flavor while having a low oil content.

Keeping up with customer trends for healthier snacks, the oil drier machine effectively reduces extra oil while also enhancing the nutritional value of Namkeen.

It also increases the product’s shelf life by lowering the moisture level, conserving the Namkeen’s freshness and quality for a longer time. Overall, the oil drier machine is essential in producing excellent, crispy, and less oily Namkeen to satisfy market needs and consumer expectations.

5. Namkeen masala Mixer Machine

The Namkeen masala mixer machine, which specializes in combining fried or dried Namkeen with a range of spices, condiments, and other flavor-enhancing substances, is an essential tool in the Namkeen manufacturing industry. Its main goal is to make sure that spices are distributed evenly, resulting in a harmonic synthesis of flavors that characterizes the distinct flavor of each Namkeen variation.

The Namkeen masala mixer machine works by blending the basic Namkeen with precisely calibrated amounts of spices and other components to produce the required flavor profile according to the particular recipe. Every piece of Namkeen is uniformly covered with savory masala thanks to the machine, which improves the overall flavor and appeals to customers.

The importance of this machinery is because of its effectiveness and accuracy. It greatly decreases the amount of time and physical labor needed for the mixing process, enabling high-quality manufacturing. This also improves production by maintaining a regulated environment for mixing and avoiding contamination and provides cleanliness and safety.

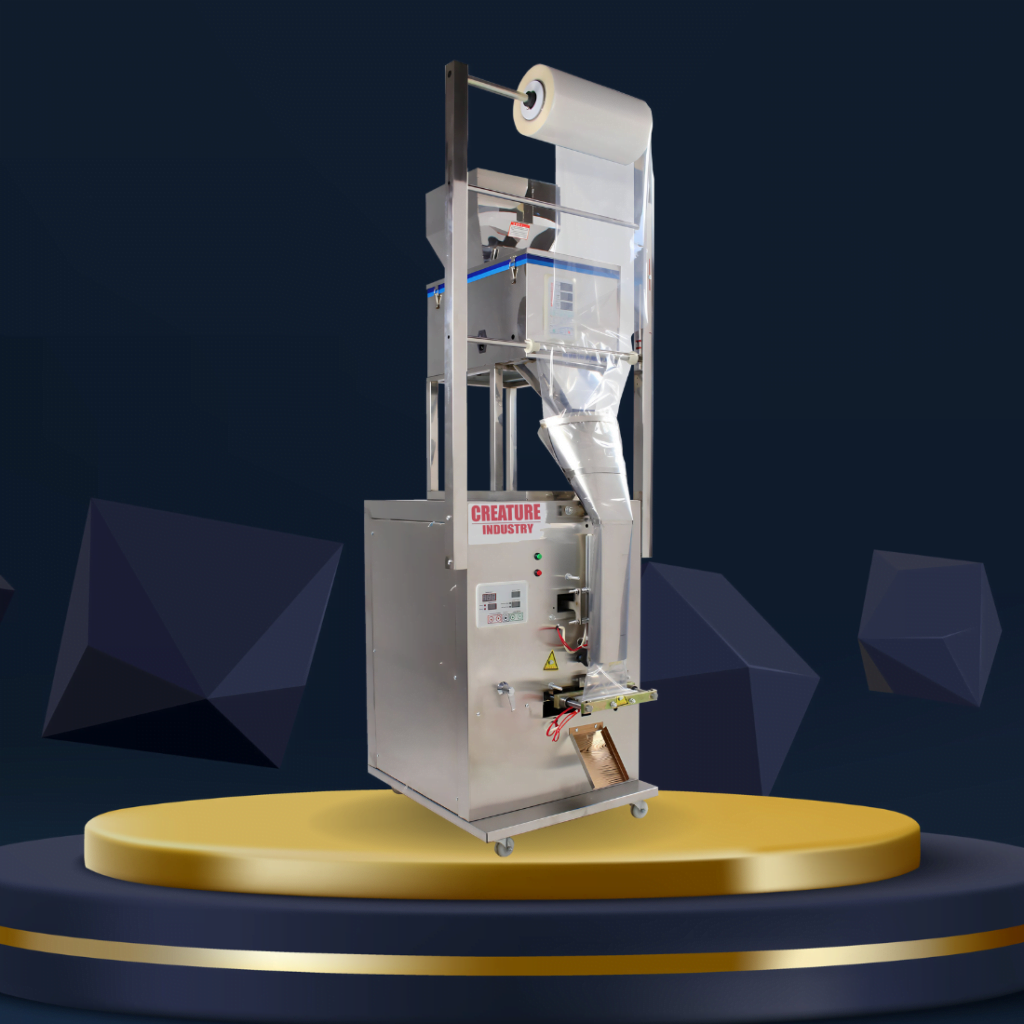

Namkeen Packing Machine

Namkeen packing machine automatically packs all types of namkeen also you don’t need to weigh the namkeen because this namkeen packing machine comes with an automatic weighing machine with gives you automatic weight and dispense facility to provide high efficiency, maintaining hygiene and precision.

You can also attach the Pneumatic system with this machine if you want to pack your namkeen with nitro air.

A namkeen Packing Machine is an advanced machine that automates the packaging process for spices and masalas. Primarily, it automates work that would be tedious and costly by hand to ensure efficiency, accuracy, and beauty in packaging.

Namkeen packing machines come equipped with advanced features such as weighers, conveyor belts, and sealing mechanisms, allowing for precise measurement and packaging. The automation not only accelerates the production process but also minimizes the margin of error, guaranteeing consistency in each packet.

Shop Now: Namkeen Packing Machine

Conclusion

All these machines are very much required for the Namkeen manufacturing industry. These machines are very important in the manufacturing of tasty, crispy Namkeen snacks that are up to consumer expectations by ensuring uniformity, efficiency, and quality throughout the production process. Each machine is essential for producing Namkeen goods, from mixing to shape, frying, drying, and flavoring.

Connect on Trade India: Creature Industry

FAQ

1. What kinds of Namkeen can be made using these tools?

These all machines and tools are used to make variety of Namkeen, including sev, bhujia chakli, gathiya, and more.

2. How can the oil dryer machine be used to regulate the amount of oil in Namkeen?

The oil drier machine effectively removes extra oil using centrifuge or other techniques, this makes Namkeen stays crispy with regulated oil levels and satisfying the expectations of health-conscious consumers.

3. Can different spice mixes be accommodated by the Namkeen masala mixer machine?

The Namkeen masala mixer machine may be modified to handle various spice mixtures, enabling a wide variety of flavored Namkeen that are in demand in market and suites the taste of customer.

4. How does the farsan machine improve the effectiveness of production?

By automating the shaping and cutting process, the farsan machine saves time and physical labor. In the result good and even shape and texture is produced.

5. Do these devices can be used by small Namkeen business owner?

Yes, these machines are available in a range of capacities, making them useful for small Namkeen manufacturing.

English

English