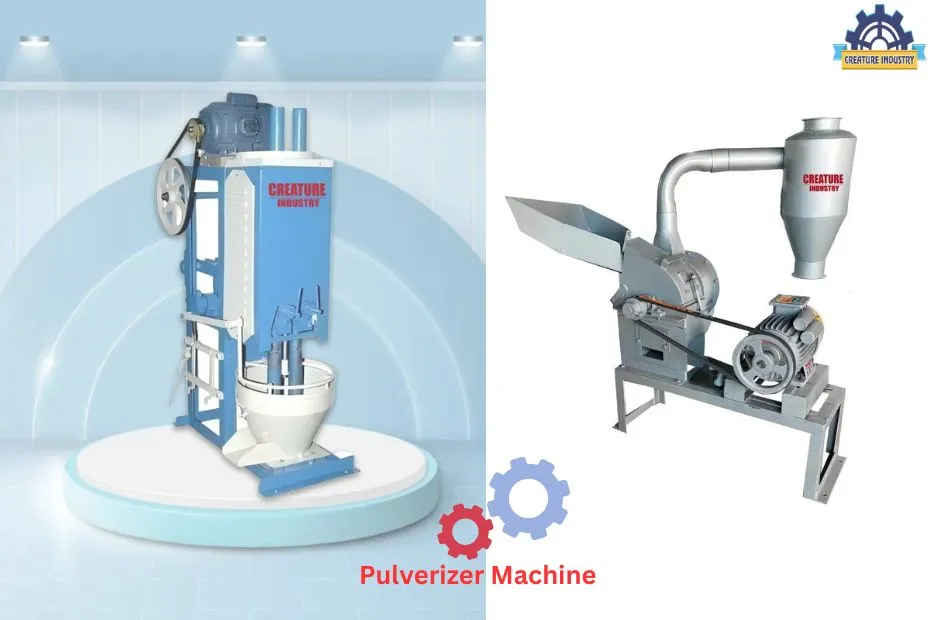

A pulverizer machine is a versatile piece of equipment essential for both commercial and residential kitchens. Whether you are running a small spice business, a large restaurant, or simply a home kitchen, a pulverizer machine can significantly enhance your ability to produce fresh, high-quality spice powders. This article delves into the applications, features, and benefits of using a pulverizer machine, with a focus on masala making machines, masala grinding setups, spice grinding setups, and chilli grinding machines.

Features of a Pulverizer Machine

- High Grinding Efficiency:

- Powerful Motor: Equipped with a robust motor capable of continuous grinding tasks.

- Fine Grinding Capabilities: Capable of pulverizing a wide range of materials, including spices, grains, and herbs, into fine powders.

- Versatility:

- Multiple Materials: Suitable for grinding various food items such as dry spices, grains, and other ingredients.

- Adjustable Settings: Allows for control over the fineness of the grind, catering to different culinary needs.

- Durability and Build Quality:

- Stainless Steel Construction: Ensures long-term durability and easy cleaning.

- Heavy-Duty Design: Built to withstand the demands of both commercial and residential use.

- Ease of Cleaning and Maintenance:

- Removable Parts: Easily disassembled for thorough cleaning.

- Safety Features: Includes safety mechanisms to prevent accidents during operation.

Applications of the Pulverizer Machine

A pulverizer machine is an essential tool in various industries for reducing materials into fine powders or granules. Here’s a detailed look at the diverse applications of pulverizer machines:

Applications in Masala Making

A pulverizer machine, often referred to as a masala making machine, is indispensable for creating fresh, aromatic spice blends both at home and in a commercial setting. Here’s how it can be utilized:

- Home Use:

- Custom Blends: Allows home cooks to create custom masala blends, enhancing the flavor and authenticity of their dishes.

- Freshness: Grinding spices at home ensures the freshest possible flavour, as pre-ground spices can lose their potency over time.

- Commercial Use:

- Consistency: Ensures a consistent grind, which is crucial for maintaining the quality and flavor profile of packaged masalas.

- Efficiency: Automates the grinding process, saving time and labor in a commercial kitchen or small spice business.

Setting Up a Masala Grinding Setup

- Residential Setup:

- Compact Design: Choose a compact pulverizer machine that fits easily into a home kitchen without taking up too much space.

- Accessibility: Place the machine in an accessible location for regular use, such as a dedicated spice grinding corner.

- Commercial Setup:

- Production Line: Integrate the pulverizer machine into the production line for seamless operation with other equipment.

- Workflow Efficiency: Ensure the machine is easily accessible for frequent use and placed near storage for raw spices.

Spice Grinding Setup

A pulverizer machine can be a cornerstone of an efficient spice grinding setup. Whether you are grinding small batches for home use or larger quantities for commercial sales, this machine can help streamline the process:

- Home Kitchens:

- Convenience: Easily grind small quantities of various spices on demand.

- Customization: Allows for the creation of unique spice blends tailored to individual taste preferences.

- Commercial Kitchens:

- Scalability: Capable of handling larger volumes, suitable for restaurants and spice businesses.

- Quality Control: Ensures consistent quality and freshness of ground spices, crucial for maintaining customer satisfaction.

Chilli Grinding Machine

A pulverizer machine is particularly effective as a chilli grinding machine, perfect for both residential and commercial applications:

- Home Use:

- Small Batches: Grind fresh chillies to create homemade chilli powder, enhancing the heat and flavor of home-cooked meals.

- Health Benefits: Ensures no additives or preservatives, providing a healthier option compared to store-bought powders.

- Commercial Use:

- High Capacity: Efficiently handles large quantities of chillies, ideal for commercial production of chilli powder.

- Product Consistency: Produces uniformly ground chilli powder, essential for product consistency in commercial sales.

Maintenance Tips for Pulverizer Machine

- Regular Cleaning:

- Clean the machine after each use to prevent residue build-up and maintain hygiene.

- Routine Inspection:

- Regularly inspect grinding components and motors for wear and tear, replacing parts as needed.

- Manufacturer’s Guidelines:

- Follow the manufacturer’s maintenance schedule and guidelines to extend the lifespan of the machine.

Conclusion

A pulverizer machine is a versatile and valuable tool for both commercial and residential use, particularly for those involved in masala making, spice grinding setups, and chilli grinding. By incorporating a pulverizer machine into your kitchen or business, you can enhance the efficiency and quality of your spice production, offering fresh, finely ground spices that elevate the flavor of any dish. Whether you are setting up a masala grinding setup for a small business or looking to improve your home cooking, a pulverizer machine is an investment that pays off in flavor, efficiency, and quality.

What is a pulverizer machine used for business setup?

A pulverizer machine is an essential piece of equipment used to grind, crush, and pulverize a variety of materials into fine powders or granules. These machines are widely used in various industries, including food processing, pharmaceuticals, agriculture, and chemical manufacturing.

Difference Between a Grinder and a Pulverizer

Grinders and pulverizers are essential machines used in various industries for processing materials into smaller particles. Although they perform similar functions, they operate differently and are suitable for different applications.

How many types of pulverizers are there?

There are several types of pulverizers, each designed for specific applications and materials. The main types include hammer mill pulverizers, impact pulverizers, ball mill pulverizers, disc mill pulverizers, attrition mill pulverizers, jet mill pulverizers, roller mill pulverizers, cryogenic pulverizers, and laboratory pulverizers.

English

English