The pouch packing machine has evolved the hustle of business packaging by providing futuristic solutions. They are vital for the food and beverages industry, the Pharmaceutical and chemicals, and the cosmetics industries through the provision of accuracy, efficiency, and hygiene. In this case, we delve into the different features that are characteristic of these pouch packing machines including Packaging Formats, Filling Mechanisms, Weighing Mechanisms, Control Systems, and Hygiene and Safety.

What is a Pouch Packing Machine?

Pouch packaging is the practice of filling products into pouches, and it is used widely in the whole food and beverage, pharmaceuticals, and consumer goods industries. Pouches are generally small and portable and are equipped with several useful options (eg., resealable zippers or spouts). Automatic pouch packing machine is widely used in production to achieve the optimum operation of this packaging process.

Using this device, all steps, from purging the pouch with the product through to packaging, can be automated to achieve maximum ones of efficiency, accuracy, and repeatability. It also eliminates the need for manual labor, does not lead to cross-contamination, and can be used for packaging a variety of pouch sizes and shapes, so it is suitable for high throughput manufacturing.

Applications of Pouch Packing Machines

Food products like snacks, spices, sugar, and tea. Pharmaceuticals such as tablets and powders. Liquids including sauces, oils, and beverages. Non-food items like detergents and cosmetics.

Specifications

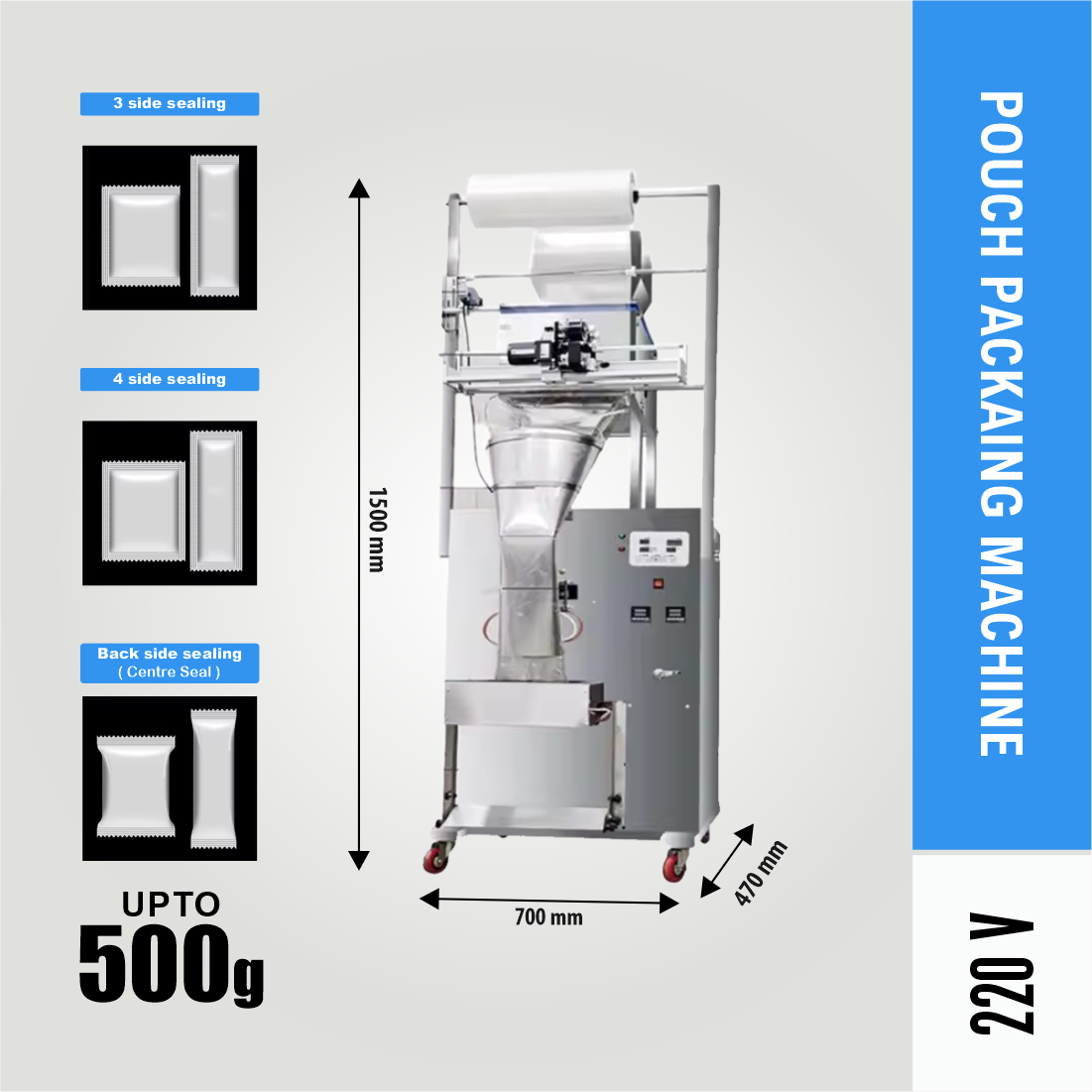

Our advanced pouch packing machine is designed for efficiency and precision. It is a wide variety of forms and compositions, with great potential to be adapted for a broad spectrum of requirements across fields and applications. Its key characteristics include the high-speed sealing mechanism, ease of use in the user interface, and durability of stainless steel construction. The machine offers stable filling with minimal spills thanks to the latest sensors and intelligent controls. It is most suitable for application in food, pharmaceuticals, and chemicals, and conforms to national safety concentration. Powerful, sturdy, and easy to use, this is a pleasant fine-touch device to assist with boosting productivity.

Features

1. Packaging Formats

Pouch packing machines are quite versatile and can be ideal for companies that have a wide array of products as they are capable of doing different packaging formats. The types of pouches that these machines can use are:

- Stand-up pouches (ideal for displaying on a shelf).

- Flat pouches (ideal for storage and transportation purposes).

- Zipper pouches (suitable for re-sealing of the product).

- Spouted pouches (great for semi-liquid and liquid items). The variety of the different styles of pouches means that a business can tailor its packaging to meet its branding and functional needs.

2. Filling Mechanism

The pouches filling mechanism is also complex since it completes a volumetric task, namely filling. Compared to simple machines, auger filling systems are particularly advanced, and machines come with a few different filling systems depending on the product:

Liquid filling: Drinks, sauces, and oils.

Viscous filling: Toothpaste, gels, and paste creams.

Paste fillings: Flavored liquid sauces that can be spread. These mechanisms reduce wastage of products while catering to the high standards of quality which in turn maximizes the profits made.

3. Weighing Mechanism

Modern pouch packing machines have very high-resolution direct weight sensors attached to enable the individual pouch weight to be much more precisely controlled. Features include.

Fast, high-performance, active load-monitoring, stacked multi-cavity weighers for use in the snack and chocolate industry. Load cell-based systems for sensitive products requiring precise measurements. A number of product mix weighers, that combine a large number of products into a single baggee, appropriate for mixed snacks or cereals. This functionality ensures compliance with the required industry standards, improved customer satisfaction, and reduced product variability.

4. Control System: User-Friendly and Intelligent

The operation of pouch packing machines is as simple as it can be done to obtain the greatest possible operation efficiency. Key elements include:

Touch-screen interfaces for easy parameter adjustments and real-time monitoring. Programmable logic controllers (PLCs) provide high-accuracy functions for machine control applications in automation. Error detection systems smoothen the detection process and to minimize the possible downtime, they try to correct errors instantly. Remote sensing-based parameters are obtained by remote sensing of electromechanical systems for the control and monitoring of processes at a distance. These intelligent agents promise a seamless operation and do not need a high level of (continuous) human control.

5. Hygiene and Safety: Protecting Quality and Operators

Hygiene and safety are of special concern in the food and pharma industries, etc. Pouch packing machines have to be highly hygienic and safe, for instance

Food contact (e.g., stainless steel with machine-to-product contact), consumer food safety. Closed chambers and closed systems to prevent contamination from being introduced into the packages. Easy-to-clean surfaces and CIP (Clean-in-Place) options for maintaining cleanliness. Protective enclosures and emergency stop systems are combined to protect the operator from personal injury during operation. Every one of these properties ensures the quality, and therefore safety, of the food consumed by the personnel.

6. High-Speed Performance and Efficiency

Pouch packing machines are built on the principle of speed and may be operated under industrial conditions to fill a very vast amount of substrate. Advanced models can compute hundreds of pouches per minute, supporting companies with tight production deadlines. Whilst these machines are high throughput, consistent quality can be achieved and errors and waste can be minimized.

7. Integration and Customization

Today’s automatic pouch packing machines boast excellent adaptability since they provide easy integration and the option to customize even more. The businesses can additionally include features such as:

Nitrogen flushing for thickness increases the durability of food items. Batch printing and date coding to ensure tracing. Different sealing techniques such as ultrasonic and heat sealing, apply to various materials.

Pouch Packing Machine Prices In India

Although the price of automatic pouch packing machines may vary on different platforms, the automatic pouch packing machines offered by Creature Industries are known for their quality and efficiency, catering to various packaging needs across different industries. These machines have a starting price of ₹50,000, making them an affordable option for small-scale businesses. For larger enterprises requiring advanced features, the price goes up to ₹2,00,000. Creature Industries offers a wide range of models to suit various needs, ensuring reliable performance and value for money. With competitive pricing and robust designs, these machines are ideal for businesses looking to optimize their packaging processes efficiently.

Conclusion

Pouch masala, chips, and namkeen packing machine is the best option for those entrepreneurs who expect to start their own brand masala, chips, and namkeen packaging and manufacturing unit. This machine can be used for the packaging of such products as ground masala, standing masala, chips, dry dates, namkeen, etc. Installation of the pouch packing machine in India will automatically weigh or count the contained entity and seal.

The operation of the Turmeric packing machine is very easy and very fast, that is, it is possible to obtain 10 to 20 pouches per minute. There is very little maintenance on this machine. All of the above machines are made of stainless steel, and all enterprises are required to choose the format in the scope of the Fssai food law.

M K Arora –

I’m using this machine from last 5 months, it’s working very smooth and fast.

rahul singh –

best quality machines

roshan yadav –

packing is very easy to use

Khan –

Best pouch packing machine

aarti goutham –

easy oprate machine machine working very easy

aarti goutham –

easy oprate machine machine

vaishu –

best pouch packing machines with advanced features. Creature Industry provides great after sales support and ensures customer satisfaction. A reliable choice for businesses in Lucknow.