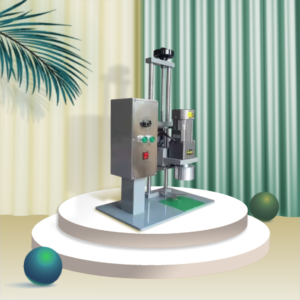

Masala packing machines are designed to effectively weigh, fill, and seal pouches of spices, ensuring accuracy, consistency, and hygiene standards. The Masala Packing Machine is a technical outfit designed for the effective packaging of colorful spice composites and powdered seasonings generally known as masalas.

These machines play a pivotal part in food assiduity by automating the packaging process, icing delicacy, speed, and thickness in the packaging of spices. They are important features and aspects associated with industrial masala packing machines.

Features

Weighing Mechanism: The machine comes with a perfect accuracy weighing system that accurately measures the selected amount of masala powder and whole masala for each pouch. Weigh scales or sensors detect the weight of the powder, ensuring consistency across pouches. The hopper of this machine is that of a weighing machine, it is directly connected to the packing machine through a connecting cable because at the time of starting both machines should work by following the same command.

Filling Mechanism: This machine depending on the specific design and configuration, the machine can use various filling tools such as Bama filler, Volume filler, Piston filler, etc to deliver the masala powder and whole masala to the packaging pouches. These mechanisms are selected based on factors such as texture and flow features for the Packaging Format of masala powder and whole masala. This machine has a hopper in which you can fill your masala powder and whole masala, chili powder, or any other spices.

Packaging Formats: Masala packing machines are very adjustable and can be adjusted into a variety of packaging formats including sachets and pouches. Fast changeover capabilities allow this machine to make seamless changes to different packaging formats to meet various market demands. You can attach a transparent roll to the masala packing machine, but if you want to attach your brand packaging roll then you replace it with a transparent roll easily.

Sealing and Labeling: After filling, this machine seals the packaging sachet to maintain the freshness and goodness of the product. Depending on the packaging format, the sealing methods may be thermal sealing or heat sealing. Additionally, inbuilt labeling systems allow you to label products with actual information such as product name, product weight, expiration date, and barcode.

Hygiene and Safety: Masala packaging machines are designed with hygiene and safety in mind, featuring hygienic manufacturing materials, easy-to-clean surfaces, and keeping our business with food-grade standards. Closed closed-loop method lowers the risk of product pollution and confirms the safety and quality of packaged masala powder and whole masala.

Control System: Most masala packing machines already have the best control system installed in them, which automatically monitors the sealing, labeling,g, and fitting of the packaging and ensures that it works correctly.

Types of Masala Packing Machines

Depending on the level of automation needed, there are various types of Masala Packing Machines Masala Packing Machines available.

Automatic Masala Packing Machine

This is a Fully Automated System with the least human input.

Best for rapid production.

Operations are done with PLC systems, making them very accurate.

Can pack in a clean way that avoids contamination.

Semi-Automatic Masala Packing Machine

Needs some human help for certain tasks.

Is cheaper for small and medium-sized businesses.

Is faster than slow machines but slower than the fastest machines.

Good for new businesses that want a low-price option.

Auger Filling Masala Packing Machine

Employs an auger screw mechanism for accurate dosing.

Ideal for packing spices of fine powder consistency.

Decreases wastage of material and variation in product.

Pneumatic Masala Packing Machine

Employs air pressure to fill and seal packs.

Ideal for bulk packs.

Most suitable for bigger industries.

How a Masala Packing Machine Works

An automated masala packing machine adheres to a particular order of operations to make certain that masala packing is accurate and efficient. The main processes are:

Step 1: Feeding Masala Powder into Hopper

The spice powder is loaded into the machine’s hopper, making certain that there is enough material to work with.

Step 2: Measuring and Weighing

Using high-precision sensors, the machine automatically measures the masala powder used for masala’s accurate packing.

Step 3: Filling Process

The spice powder that has been measured is filled in pre-created pouches or sachets.

Step 4: Sealing and Cutting

The pouches are sealed using heat sealing or vacuum sealing techniques to preserve the masala for an extended period.

Step 5: Labeling and Printing

Certain Masala Packing Machines come with batch coding and labeling devices that print the essential details of the expiry date, manufacturing date, and batch number.

Choosing the Right Masala Packing Machine

Choosing the right Masala Packing Machine requires careful consideration of several factors:

Production Capacity: Figure out how much you need to produce in an hour or a day.

Automation Level: Decide if you require an automatic or semi-automatic machine.

Budget: Determine if you would be able to meet the purchase, installation, and maintenance costs.

Energy Efficiency: Consider models that will save you money on your electric bill.

Material Compatibility: Check if the machine accommodates various spice powders.

Price Range

Check out our masala packing machine, priced between ₹25,000 and ₹1,80,000! This versatile machine simplifies the process of packing your spices, ensuring a neat and professional finish for your products. It’s easy to operate, offers adjustable pouch sizes, and delivers efficient performance. Don’t miss out on our limited-time discounts—explore the best masala packing machine price today

Vivek kumar –

Easy oprating

Aman –

Working is good

Chakani –

Polite behaviour

Rao –

Best machine

Babar Khan –

Machine is very good but prices may be need to decrease

Vaishnavi –

Good for standard Packaging/ for standard packing

navi –

World best machine

Lavi –

Accurate weight no extra weight

Balmiki –

All requirements are full in this machine

Barouni shab –

Rate is too costly

Suraj –

For Grind masala best machine