Designing a commercial kitchen setup for your restaurant or hotel involves meticulous planning and the selection of specialized kitchen equipment to ensure efficiency, productivity, and compliance with health regulations. The right equipment can significantly enhance the workflow and quality of food and beverages served, contributing to the overall success of your establishment. This article explores essential machines for a commercial kitchen, a cloud kitchen, and a restaurant setup, focusing on specific product keywords to illustrate their importance and functionality.

Setting up a successful food-related business involves strategic planning and investment in essential equipment. A mini atta chakki plant is a vital addition for those aiming to offer freshly milled flour, ensuring top-quality, fresh ingredients for various culinary creations. Equally important is the selection of the right kitchen equipment to streamline operations and enhance productivity. A well-planned restaurant setup that incorporates advanced kitchen tools and appliances can significantly improve efficiency and food quality. By integrating a mini atta chakki plant, appropriate kitchen equipment, and a strategic restaurant setup, businesses can create an optimal environment to meet the demands of modern culinary practices and exceed customer expectations.

List of Commercial Kitchen Equipment

Beverage Preparation Equipment

Sugarcane Juice Machine

Incorporating a sugarcane juice machine is essential for establishments that offer fresh, natural beverages. These machines are designed to efficiently extract juice while preserving the natural sweetness and nutritional benefits of sugarcane.

- Features: High extraction efficiency, easy-to-clean design, stainless steel construction to prevent rust, and user-friendly operation.

Benefits: Provides fresh, healthy juice quickly, catering to the growing demand for natural, refreshing drinks.

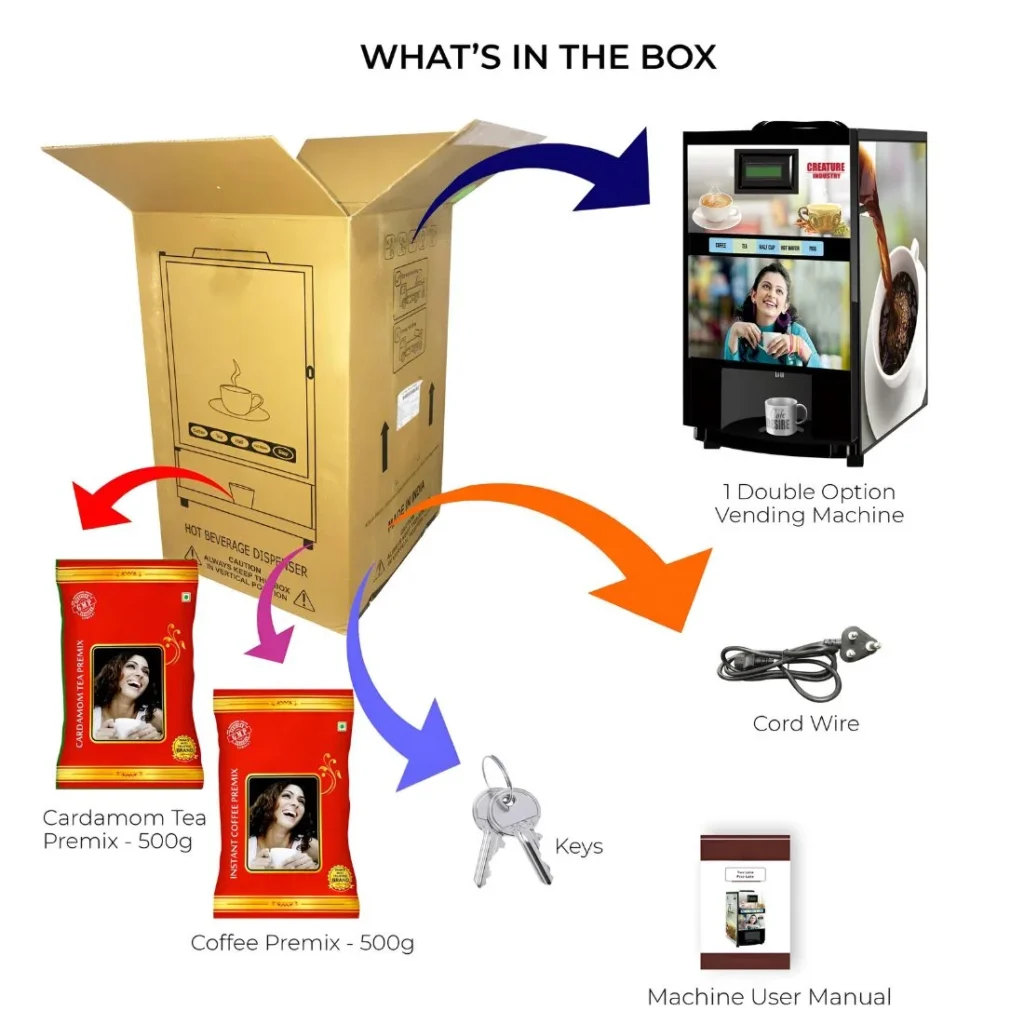

Coffee Machine

A coffee machine is indispensable in any commercial kitchen, particularly in hotels and restaurants that offer breakfast services or have an in-house café.

- Types: Espresso machines, drip coffee makers, and pod coffee machines.

- Features: Consistent brewing temperature, high capacity, programmable settings, and steam wands for milk frothing.

- Benefits: Delivers high-quality coffee drinks, enhancing the guest experience and boosting morning sales.

Snack Preparation Equipment

Potato Chips Machine

A potato chips machine is a must-have for restaurants that serve this popular snack. It allows for the quick and efficient production of crispy, golden potato chips.

- Features: Automated slicing, uniform thickness control, and high-capacity frying capabilities.

- Benefits: Consistent quality and taste, meeting customer expectations and reducing preparation time.

Dairy Product Preparation Equipment

Mawa Making Machine / Khoya Making Machine

Mawa, also known as Khoya, is a crucial ingredient in many Indian sweets and dishes. A mawa making machine, also referred to as a khoya machine, streamlines the production of this ingredient.

- Features: Heavy-duty construction, efficient heating systems, and automated stirring mechanisms.

- Benefits: Produces consistent, high-quality mawa, reduces manual labor, and increases productivity.

Paneer Press Machine

Paneer is a staple in many Indian cuisines. A paneer press machine ensures the production of firm and uniform paneer.

- Features: Adjustable pressure settings, stainless steel construction, and easy-to-clean components.

- Benefits: Consistently firm paneer, enhancing the quality of dishes and ensuring customer satisfaction.

Vegetable and Fruit Processing Equipment

Imported Vegetable Cutter Machine

An imported vegetable cutter machine is essential for rapidly and uniformly chopping vegetables, which is crucial for maintaining consistency in dishes.

- Features: Multiple cutting blades, high-speed operation, and durable construction.

- Benefits: Reduces preparation time, ensures uniform cuts, and enhances kitchen efficiency.

Fruit Pulper Machine

A fruit pulper machine is ideal for making purees and pulps from various fruits, essential for desserts, beverages, and sauces.

- Features: High extraction rate, stainless steel body, and easy maintenance.

- Benefits: Consistently smooth fruit pulps, enhancing the texture and flavor of dishes.

Workflow Optimization and Safety

Setup Considerations

When designing a commercial kitchen setup, consider the flow of operations from storage to preparation, cooking, and service. Ensure that the placement of each machine facilitates a smooth workflow.

- Storage Area: Start with ample dry and cold storage near the entrance to streamline the delivery process.

- Refrigeration Units: Place walk-in coolers/freezers and reach-in refrigerators for perishable items.

- Dry Storage: Use shelving units and storage bins for non-perishables.

- Preparation Area: Adjacent to storage, this area should be equipped with prep tables and sinks.

- Sugarcane Juice Machine: Place near the beverage prep area.

- Imported Vegetable Cutter Machine: Position near the prep tables for easy access.

- Fruit Pulper Machine: Locate near the preparation sinks for washing and processing fruits.

- Cooking Line: The heart of the kitchen is where most of the cooking takes place.

- Mawa Making Machine / Khoya Making Machine: Position these near the cooking area for easy access to stoves and heating elements.

- Potato Chips Machine: Place near the frying section.

- Service Area: Where dishes are plated and sent out to diners.

- Paneer Press Machine: Position close to the cooking area but accessible to the service staff for quick retrieval.

- Beverage Station: Dedicated space for coffee and juice preparation.

- Coffee Machine: Place in an easily accessible area for staff to prepare beverages efficiently.

Ensuring Safety and Compliance

- Ventilation: Install proper exhaust hoods and ventilation systems to manage heat and smoke.

- Sanitation: Use stainless steel surfaces for easy cleaning and maintenance.

- Fire Safety: Equip the kitchen with fire suppression systems and extinguishers.

Energy Efficiency and Sustainability

- Energy-Efficient Appliances: Invest in energy-efficient machines to reduce operating costs.

- Sustainable Practices: Implement waste management systems, including recycling bins and grease traps, to comply with environmental regulations.

Training and Maintenance

- Staff Training: Ensure that staff are trained to use each machine efficiently and safely.

- Regular Maintenance: Schedule regular maintenance to prolong the lifespan of the equipment and ensure optimal performance.

Conclusion

Designing a commercial kitchen setup for a restaurant or hotel requires careful consideration of equipment that enhances efficiency, productivity, and quality. By incorporating specialized machines such as sugarcane juice machines, potato chips machines, coffee machines, mawa making machines, khoya making machines, imported vegetable cutter machines, fruit pulper machines, khoya making machines, and paneer press machines, you can create a well-organized and functional kitchen. This will not only improve the workflow but also ensure the consistent quality of food and beverages, ultimately leading to greater customer satisfaction and business success.

English

English