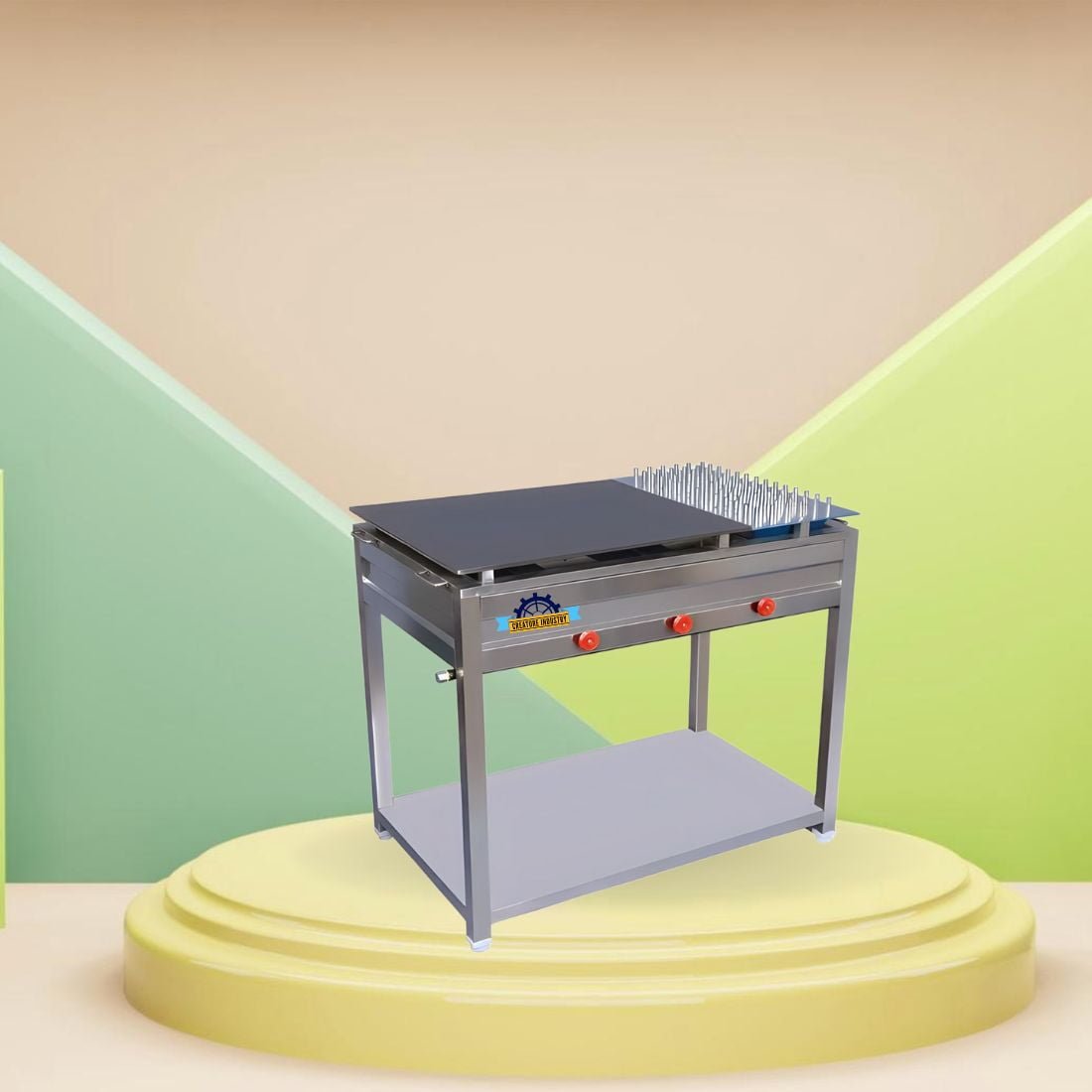

Dough sheeter Machine

₹18,000

Specification/Additional Details

- Automation Grade: Automatic

- Electric

- Weight: 70KG

- Voltage: 220V

- Dimension: 27X19X30

- Material: Stainless Steel

- New Only

- Made in India

Price Range – ₹18000 to ₹55000

The uniform rolling of dough is made possible by a particular apparatus known as a dough sheeter machine which customizes the thickness of the dough. Given that it is automated, the machine will remove the inconsistencies that come with manual rolling. With the help of flexible rollers, these devices can roll thin sheets of pastry dough to foods that would make dough for bread and pizza.

Dough sheeters are an invaluable piece of machinery used in the baking commercial and food preparation industry. Businesses benefit greatly when these machines are used because they conserve labor hours, increase productivity, and maintain the desired quality for all items produced. The operation of a bakery, pizzeria, restaurant, or pastry shop can be optimized to a great extent with the right selection of dough sheeters. This detailed guide will provide you with the necessary information about the different varieties of dough sheeter machines, their key features, the benefits they offer, and instructions on how to select the most suitable machine.

Types of Dough Sheeter Machines

Dough sheeters come in various models, each catering to specific applications. Here are the most common types:

Manual Dough Sheeters

To roll out the dough with these particular machines, you need to hand-crank them. They are best suited to small bakeries and home kitchens with low production volume.

Pros: Easy to use.

Cons: Not suitable for high-volume production and are labor intensive.

Semi-Automatic Dough Sheeters

Slightly better than manual versions, semi-automatic dough sheeters have an electric motor that helps in rolling, but some manual work is required.

Pros: These are more efficient and faster than manual sheeters.

Cons: Cannot be operated as fully automated, because of the semi-automatic features, and needs manual interference at times.

Fully Automatic Dough Sheeters

These machines are intended for high-scale manufacturing as they fully automate the entire process, making sure that dough rolling posts are set at a particular height so it stay the same thickness at any height.

Pros: Effectively boosts productivity, saves valuable time, and cuts down on costs.

Cons: Very costly and needs increased space.

Reversible Dough Sheeters

These models enable the motion of the sheeted dough, while the powered belts roll the dough back and forth into the desired thickness.

Pros: Great for sensitive products such as croissant and puff pastry.

Cons: More than ‘standard’ model prices.

Key Features Of Dough Sheeter Machine

When buying a dough sheeter machine, please take the following specifications into account to make the right decision for your own company:

- Dough Thickness Control: For an optimal dough sheeter, it should be possible to reach the given maximal thickness.

- Conveyor Belt Size: A larger conveyor belt accommodates bigger batches, increasing productivity. Ensure the belt size matches your production needs.

- Motor Power: The reliable and reproducible motor action in the absence of thermal damage, especially repeated motor actions, is offered by the strong motor.

- Safety Features: Models including emergency stop buttons, guards, and auto power-down protection are brought together for a safety guarantee for the operator.

- Build Quality and Material: Stainless steel is robust, it is easy to wash, and also corrosive resistant, so is greatly suited to food processing.

- Ease of Cleaning and Maintenance: The due and simple substitution of machine parts to the high ease of replacement of machine parts allows for easy and thus guarantees that the machine complies with hygienic regulation requirements in the canteen.

- Footprint and Portability: Consider the available space in your kitchen. Folding tables or caster wheels are optional in dough sheeters to allow device portability.

Dough Sheeter Machine Price Range

Toothed dough sheeters are prevalent in bakeries, restaurants, and other food outlets which require the rolling or sheeting of dough. In India, these machines come at various prices depending on the brand, size, and features. What this means is that manual models start at about 50,000 and large fully automatic industrial machines fetch about 500,000. Semi-automatic machines which fall in the midrange category cost around 100,000 to about 300,000. The price ranges are also affected by the level of automation of the machine, the body being made of stainless steel, roller width, and motor power. Always compare brands before buying and check the warranty provided.

Benefits of Using a Dough Sheeter Machine

- Consistency: The consistent thickness that a dough sheeter offers is by far its greatest benefit. This guarantees that every pizza crust or pastry is the same size and texture, which is essential for preserving the quality of the final product.

- Time Efficiency: You may cut labor costs and save time by automating the dough sheeting process. By eliminating the need to hand roll out the dough, bakers may now concentrate on other crucial duties.

- Space-Saving: For smaller bakeries, compact machines like the Bakery Rolling MachineSmall provide great space-saving options without sacrificing functionality.

- Ease of Use: Dough sheeters, whether they are electric or manual, are made to be easy to use. Employees can quickly become proficient with this equipment even if they have no prior expertise.

How to Choose the Right Dough Sheeter

The best dough sheeter for a business is determined by its requirements, budget, and the production capacity of the venture.

- Assess Your Production Volume: A manual or semi-automatic dough sheeter should be used by small-scale enterprises. However, fully automatic models are ideal for high-volume bakeries.

- Consider Your Space Availability: Floor-standing models are more convenient for big businesses, and compact models are ideal for small kitchens.

- Evaluate Your Budget: You had better be sure that the investment aligns with your budget while taking the features of the high-end dough sheeters into account.

- Look for Reputable Brands: Choose a manufacturer known for quality, durability, and after-sales support.

- Check Warranty and Customer Support: A good warranty ensures peace of mind. Also, make sure there are spare parts and maintenance services available.

How to Operate a Dough Sheeter Machine

A dough sheeter machine (DSM) is certainly one of the most important machines in bakery, pizza, and patisserie stores, which can spread in a homogeneous and effective way large amounts of dough. Proper operation ensures efficiency, safety, and high-quality results. Follow these steps to operate a dough sheeter machine

Preparation

Read the User Manual: Always, please, refer to the manufacturer’s instructions for advice on how to do so and, by the way, protect your health.

Prepare Dough: Verify dough is at the appropriate temperature and stickiness level so that it will not rip or become lodged.

Examine the device: Make that the machine is clear of any impediments, clean, and correctly constructed.

Setting Up the Machine

Power On: Plug in the machine and turn it on.

Adjust the Rollers: Determine the rollers’ starting thickness based on your requirements.

Dust with Flour: To keep the rollers and conveyor belts from sticking, lightly dust them with flour.

Working with the Machine

Feed the Dough: A piece of dough is flattened before being deposited on the conveyor belt or rolled over by the rollers.

Start Rolling: Place the dough into the rollers and start them. Depending on the desired thickness.

Adjust Thickness: Slowly tighten the gap on the rollers.

Repeat if Necessary: For extremely thin sheets, pass the dough through the rollers more than once, progressively getting thinner each time.

Safety Guidelines

Keep Hands Clear: When the machine is on, do not get close to the rollers with your hands.

Do Not Use Hands When Necessary: If using hands is a concern, then a dough pusher or scraper is preferable.

Switch Off Whenever Needed: The machine should always be unplugged after use when being cleaned or altered.

Cleaning and Maintenance

Turn Off and Unplug: Always ensure the machine is powered off before cleaning.

Clean up: Remove any leftover dough with a scraper or brush.

Wipe down with a damp cloth: wash rollers and conveyor belt with a damp cloth and wash the solution diluted.

Lubricating moving components: If desired, supplement the necessary components with food-grade lubricant following manufacturer criteria.

Troubleshooting Most Common Problems

Dough Sticks: Confirm the moisture in the dough is at the required level or add more flour.

Thickness is not uniform: Always confirm that the rollers have been adjusted correctly as well as ensure the dough is mixed adequately.

The Machine Will Not Operate Properly: Scraping off any dough leftovers has to be done first along with stopping the equipment and checking fittings and screws.

Best Dough Sheeter Machines in the Market

Somerset CDR-2000

Type: Reversible Automatic Dough Sheeter

Pros: High-speed performance, stainless steel construction, user-friendly controls

Best For: Commercial bakeries and restaurants

Fimar 520BL

Type: Automatic Dough Sheeter

Pros: Robust build, excellent consistency, versatile applications

Best For: Medium to large-scale production

DoughXpress DXSM-270

Type: Semi-Automatic Dough Sheeter

Pros: Affordable, compact, easy to use

Best For: Small bakeries and home use

Omcan Tabletop Dough Sheeter

Type: Manual Dough Sheeter

Pros: Budget-friendly, compact design

Best For: Home kitchens and small bakeries

Top FAQS About Dough Sheeter Machine

Conclusion

Whether you choose a more hands-on approach or high-volume manufacturing, a Bakery Dough Sheeter Machine is an essential tool for any bakery. There is a machine for every purpose, ranging from the small, portable Dough Sheeter Machine for confined locations to the classic manual Bakery Rolling Machine for artisanal control. Selecting the ideal dough sheeter will guarantee that your bakery’s dough is consistently rolled out flawlessly, enabling you to provide your clients with high-quality goods.

1 review for Dough sheeter Machine

Related products

-

-

Chili Cutter Machine

₹9,000 -

3 Burner Chapati bhatti

₹13,000

English

English

Kristy –

best efficient machine.