Auger Filling Machine

₹180,000 Original price was: ₹180,000.₹150,000Current price is: ₹150,000.

| Product Name | Auger Filling Machine |

| I Deal In | New Only |

| Brand | Creature Industry |

| Country Of Origin | Made In India |

| Capacity | 10g To 2kg |

| Usage/Application | To pack powders |

| Voltage | 415V |

Auger filling machines provide accurate and repeatable filling of powder and granules using a screw mechanism to fill the product. They are available in different varieties— fully automatic, semi-automatic, dual head, and VFFS, catering to the food, pharmaceutical, chemicals, and cosmetic industries. They also improve productivity to accuracy, precision, minimal wastage, and scalability. Product type, speed of automation, and budget all play a deciding factor when choosing the right device. Regular maintenance, calibration, and cleaning further boost additional performance. The machines also enable high-standard production requirements to be met with improved productivity.

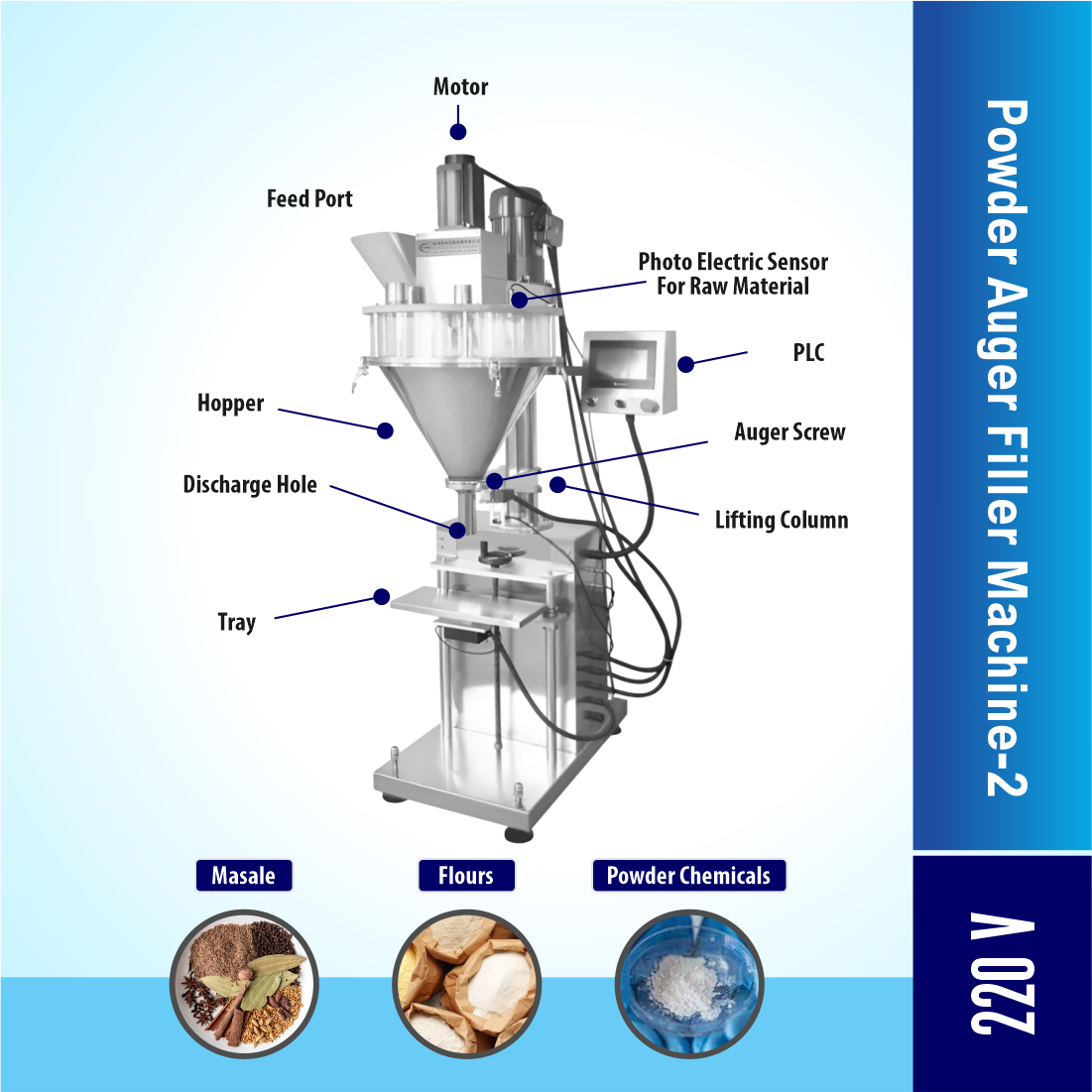

What is an Auger Filling Machine?

An Auger Filling Machine is an extremely high accuracy filling machine for hygroscopic, powdery, and/or granular products, for example. flour, spice, and protein powder, into containers or bags. It is powered by a rotary auger screw and thus it is possible to achieve high accuracy and reproducibility of charge-level filling. Such already exist as machines are used for the food, pharmaceutical, and chemical industries to obtain efficient, dust-free packages, etc.

How Does an Auger Filling Machine Work?

The principle followed by the auger filling system is simple but effective at the same time.

Product Hopper: The material that is to be filled is stored in a hopper that is positioned above the machine.

Auger Mechanism: The rotating auger screw turns and dispenses the appropriate amount of product.

Filling Nozzle: The powder is funneled through a nozzle and into the containers, pouches, or bottles.

Control System: More advanced models utilize programmable Logic Controllers for more sophisticated and accurate adjustments that minimize product loss.

Types of Auger Filling Machines

1. Semi-Automatic Auger Fillers

These machines are most efficient for low and moderate output levels. Manual loading of containers is required and is done via a foot switch or push button.

2. Fully Automatic Auger Fillers

Best for high production output and easily integrates into production lines with conveyor belts. Heavy investments into automation lead to quicker and better packaging.

3. Vertical Form Fill Seal (VFFS) with Auger Fillers

Applicable in industries that necessitate pouching. Performs the tasks of pouch making, filling, and sealing all in one go.

4. Dual Head Auger Fillers

Left unchecked, fill speeds can lead to inaccurate dosing of products as well as compromised precision. Best suited to cover fill lines that allow a faster fill rate and greater volume.

Key Features of an Auger Filling Machine

Precision and Accuracy of Filling Volume Auger Capable of Accepting Difficult-to-Flow Powders Provide High Precision Control Over Filling Volume.

Multi-Use Functions Pieces Suitable For All Spices Like Protein Powder, Pharmaceutical Powders, Chemical Powders and Many Others. Adjustable Speed and Volume Settings Meet Various

Different Packaging Requirements.

Compliance With Food and Pharmaceutical Standards Easy To Clean Machine Parts Made From Stainless Steel And Easy to Maintain, Tool-Free Disassembly.

Adjustable Fill Height Provides Flexibility In Packaging Height Compatible With Widely Used Bottles, Pouches, Jars, and Containers.

Auger Filling Machine Price Range

The price of an auger filling machine ranges depending upon its features, capacity, and brand of the manufacturer. They tend to range between ₹180,000 to ₹250,000 by the specifications of the manufacturer. The level of automation, the material used, and the brand have a direct impact on the price. For those looking to purchase auger filling machines, Creature Industry offers a high-quality machine for ₹150,000. This allows businesses to purchase a reliable and efficient filling machine without going over budget.

Industries That Use Auger Filling Machines

1. Food Industry

The variety of products routinely available by auger fillers are powdered milk, coffee, spices, flour, and protein powder. Ensures uniform filling and prevents contamination.

2. Pharmaceutical Industry

Used for medical powders, supplements, and vitamins. Maintains dosage accuracy, crucial for regulatory compliance.

3. Chemical Industry

Ideal for detergents, pesticides, fertilizers, and other powdered chemicals. Ensures minimal dust emission and product loss.

4. Cosmetics Industry

Fills talcum powder, facial powders, dry shampoos, etc. Maintains consistent texture and volume.

Advantages of Using an Auger Filling Machine

1. Consistent and Precise Filling

Eliminates human error in manual filling processes. Servo motor control ensures repeatable accuracy.

2. Increased Efficiency and Productivity

Automated models significantly reduce labor costs. Model performance can be translated to provide the throughput of a hundred to a thousand of boxes per hour.

3. Minimal Product Waste

Reduces spillage and loss of high-value powdered products. Ensures proper material utilization.

4. Customization and Scalability

Machines can be program-specific to varying product densities and fill weights. Expandable features allow businesses to scale up operations.

How to Choose the Best Auger Filling Machine

1. Think About the Kind of Product Involved.

There is a challenge with finely powdered products as they may require a more sophisticated system for dust control. Different types of auger configurations are required for granular products.

2. How Fast and Accurate Does it Need to Be?

If production is of medium scale, then the machine should be in moderate operation. There seems to be justification for purchasing this model based on the fillings’ premium good estimates.

3. Levels of Automation

Small-scale businesses can benefit more from semi-automatic models. Only fully automatic machines should be used for large-scale production.

4. Objectives of Profit and Budget

The consideration of return on investment can be made when buying an auger filling machine. The price range after calculating total expenses including service and administrative costs should be considered.

Maintenance and Troubleshooting Tips

1. Regular Cleaning and Maintenance

Prevents powder buildup, which can affect accuracy. Food-safe cleaners should be used for stainless steel surfaces.

2. Check Auger Alignment and Wear

Misaligned augers can cause inconsistent fills. Replace worn-out augers periodically to maintain efficiency.

3. Calibrate and Test Periodically

Regular calibration ensures continued accuracy and reliability. Conduct test fills to verify performance.

4. Address Common Issues

Inconsistent fill levels? Check the auger speed and product flow. Machine clogging? Ensure that the hopper is free from obstructions.

Conclusion

Businesses that need to fill powders and granules with precision will find the auger filling machine to be an indispensable tool. With precision and effectiveness, the machine achieves multi-sector packing purposes. From food to pharmaceuticals and chemicals and cosmetics, the right choice of auger fillers will streamline production while guaranteeing quality.

Related products

-

-

Liquid Filling Machine

₹55,000 -

Shrink Tunnel Machine

₹40,000

English

English

Reviews

There are no reviews yet.