Description

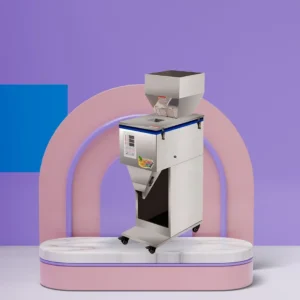

Semi automatic weigh filling machine up to 200 gm is good for determining or checking the weight of particulars without the intervention of a driver and is generally used in specialized cases within a product cycle. The 1kg small-volume filling machine is suitable for tea-scented tea, black tea and green tea, dry goods, and special products, tackle accessories, electronic factors, screws and nuts, whole grains, fruits and vegetables, quick-frozen dumplings, cat food and dog food, fertilizer feed, Quantitative and weighing of medicines, red dates, wolfberry, potato chips, popcorn, nuts and melon seeds, corn seeds, coffee beans, coffee powder, flour, pepper powder, seasoning powder, powder, bar shape, irregular materials, etc. filling.

Their approval conditions and operation circumstances are other than non-automatic outfits and more detailed advice regarding their felicity for use can be acquired from your original trading norms service.

Maintenance and Use of Semi Automatic Weigh Filling Machine

1. Automatic weighing machine should be used on a stable, vibration-free, position face. Most equipment incorporates a position-index device, which must indicate that the equipment is positioned when in use.

2. The Weighing Machine must be rightly balanced before use, with any pointers reading zero( on the electronic importing outfit the digital suggestions shouldn’t be blank previous to importing). Still, incorrect readings may be given If the importing outfit doesn’t indicate zero before use.

3. Strong draughts, caused by breath or air exertion systems, can affect some importing equipment and this should be considered when opting for the position the machine will be used in.

4. The weighing pan should be kept clean and free from any debris or obstructions beneath it. A figure of debris or other material under or conterminous to the weighing visage can intrude with the accuracy of the Semi automatic weigh filling machine.

5. Regular checks of the accuracy of the weighing machine should be carried out using known amounts, similar to stamped weights, to help ensure weighing outfit doesn’t come defective or unjust.

6. A record of the checks that are carried out on a semi-automatic weigh filling machine should be kept; it must identify when they’re done, the action taken, the results of the reviews and who took them out, together with any required remedial action taken.

7. A maintenance contract with a weighing machine service company should be considered, especially where a weighing machine is in constant use or veritably high situations of weighing accuracy need to be maintained.

Applications

Spices & Masala Powder

Tea & Coffee

Dry Fruits & Seeds

Detergent Powder

Ayurvedic Powder & Herbal Products

Granules, Grains, and Sugar

Advantages

Compact layout which is great for small businesses or tight spaces.

Easy to operate with minimal training

Low maintenance and energy-efficient

Consistent weight accuracy for professional packaging

Reduces product wastage and improves productivity

Key Features

Weighing Capacity: 10g to 200g.

Accuracy: From.5 to 1 gram (by product type).

Operation Type: Semi manual (auto fill).

Material Contact Parts: Stainless Steel (304/316).

Control Panel: For precise adjustment of.

Output Speed: Per minute 8 15 of which may vary with product flow and operator efficiency.

Discharge System: Vibrated or by gravity based on product texture.

Conclusion

This is an automatic weighing and filling machine. The microcomputer controls the tone-energy touch-operated packing system and also measures from 1 gm to 200 gm. We develop and produce this provident and effective direct weigh padding and sealing unit. The importing speed and accuracy are controlled through vibration strength and accouterments consistency, low investment, easy operation,n, and conservation.

A semi-automatic weigh filling machine is suitable for packing grains, beats, Grains, Seeds, Nuts, Sugar, etc. This Machine runs easily is stoner-friendly and low noise. Small size, Light Weight, malleable Quilting Speed. Show quilting weight and figures of packages. Contact parts are made of Stainless Steel.

Reviews

There are no reviews yet.