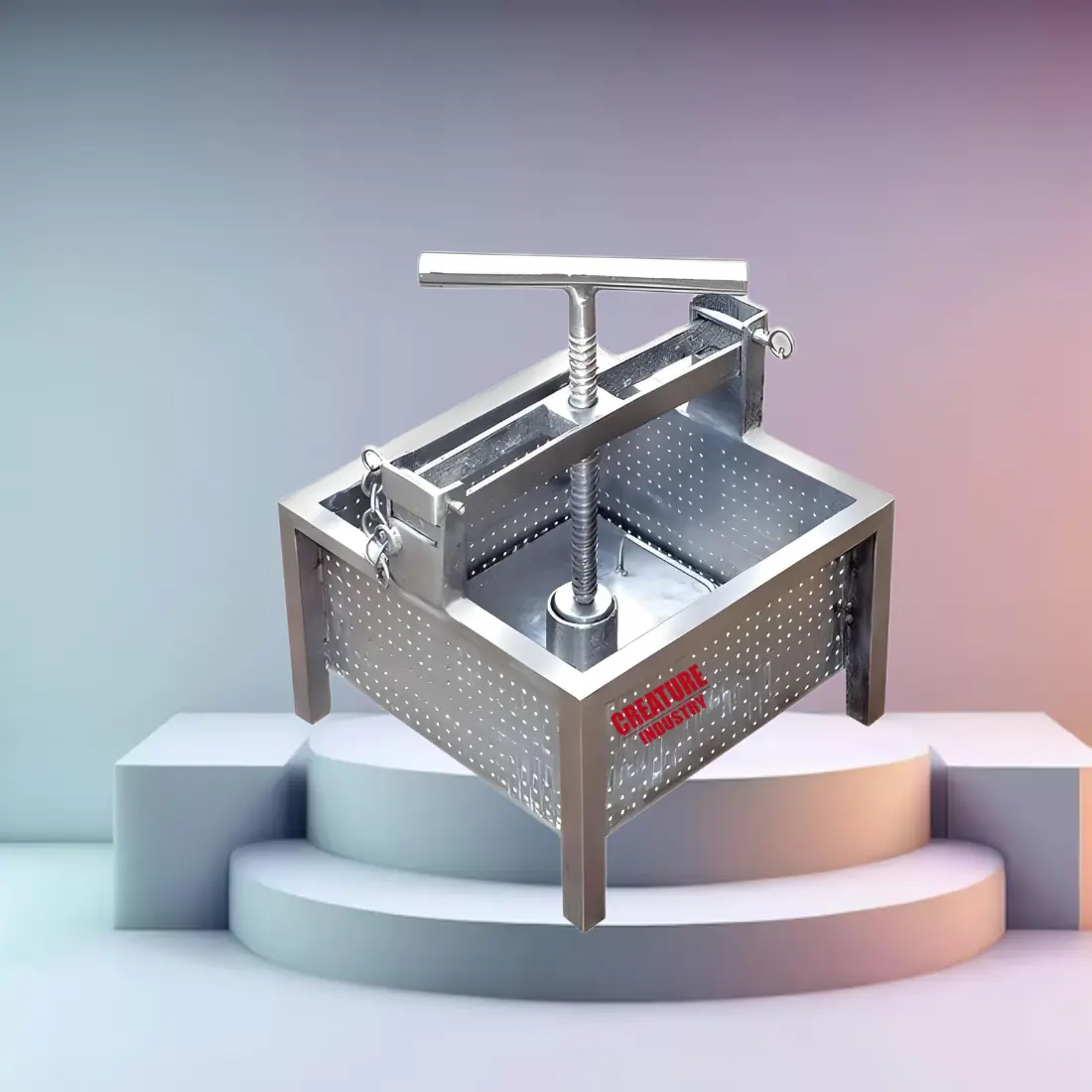

Paneer Press Machine

₹8,000

Price Range – ₹8000 to ₹14000

| Name | Paneer Press Machines |

| Automatic Grade | Manual |

| Electricity Connection | Single Phase |

| Power Source | Electric |

| Design Type | Customized |

| Automation Grade | Automatic |

| Machine Body Material | stainless steel |

| Equipment Type | Paneer Press |

| Production Capacity | Upto 100 kg |

| Brand | Creature Industry |

| Warranty | 1 Year |

| I Deal In | New Only |

| Application | Used for shaping and pressing paneer. |

A paneer press machine is a specialized device designed to press curdled milk into a firm and uniform block of paneer. By applying controlled pressure, the machine ensures the removal of excess whey while maintaining the structure of the paneer. These machines come in various designs, ranging from manual to fully automatic systems, catering to both small-scale producers and large dairy industries.

Types of Paneer Press Machines

1. Manual Paneer Press Machines

Easy to use, affordable, and electricity-free. It is made up of a weight and a pressing plate on a frame that exerts pressure on the whey to drain it. Perfect for home or small-scale use, but labor-intensive.

2. Hydraulic Paneer Press Machine

improves texture by applying even, controlled pressure using hydraulic pressure. Compared to manual presses, it takes less manual labor and is appropriate for medium- to large-scale production.

3. Electric Paneer Press Machines

The most sophisticated; it operates automatically by use of an electric motor that supplies steady pressure. Though costly and electricity-dependent, it is perfect for large-scale production.

Key Features Of Paneer Press Machine

When choosing a paneer press machine, consider the following features to ensure optimal performance:

- Crafted from premium stainless steel to provide lasting functionality and corrosion resistance

- Enables exact control over pressing pressure to give paneer the right texture and hardness.

- easy-to-use design with a straightforward mechanism for effective and convenient use.

- Made using materials that are safe for food and surfaces that are easy to clean in order to maintain high standards of cleanliness.

- Effective performance in a space-saving design, ideal for commercial or small-scale applications.

How to Operate a Paneer Press Machine

Step-by-Step Process:

- Prepare the Milk Curd: Start with high-quality milk to ensure the best paneer.

- Fill the Machine: Place the curdled milk in the pressing compartment.

- Apply Pressure: Adjust the pressure according to the desired paneer firmness.

- Drain the Whey: Allow the excess liquid to drain completely.

- Remove the Paneer: Once the process is complete, carefully extract the paneer block.

Maintenance Tips for Paneer Press Machines

- Regular Cleaning: Wash all components thoroughly after use to prevent residue buildup.

- Lubrication: Keep moving parts well-lubricated to ensure smooth operation.

- Inspection: Periodically check for wear and tear, especially in high-pressure systems.

- Storage: Store the machine in a dry and clean environment to prevent rust.

Conclusion

A paneer press machine is an indispensable tool for anyone involved in paneer production, whether at a small scale or an industrial level. By choosing the right machine and following best practices, you can ensure consistent quality, improved efficiency, and significant cost savings.

Related products

-

3 Burner Gas Range

₹12,000 -

2 Burner Gas Range

₹18,000 -

English

English

Reviews

There are no reviews yet.