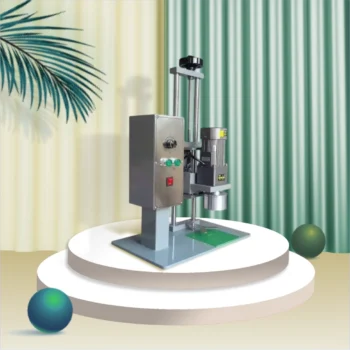

Description

In the modern packaging industry, sealing machines play a crucial role in ensuring product safety, longevity, and aesthetic appeal. These cutting-edge machines are good at sealing up all kinds of containers like plastic bags, cartons, pouches, and bottles. This keeps the stuff inside safe from germs and spills as well as other factors that might spoil the items. Investing in a high-quality sealer machine can raise yields and product quality. Whether you are sealing food, pharmaceuticals, beauty products, or industrial components, top-quality equipment benefits all.

Types of Sealing Machines

Impulse Sealing Machine

Impulse sealers employ an electric current to create heat for sealing thermoplastic materials. These machines suit poly bags and other forms of plastic packaging. They are common in the food, electronic, and medical sectors because of their efficiency in terms of speed and reliable sealing quality.

Continuous Band Sealing Machine

A continuous band sealing machine is an automated machine that works at high speed for sealing bags and pouches. It ensures consistent sealing which is airtight, leak-proof, and tamper-proof sealing in bulk business. These characteristics make it suitable for firms that need maximum productivity.

Induction Sealing Machine

An induction sealing machine applies electromagnetic induction to place a hermetic seal over the mouth of a bottle cap in the pharmaceutical and food industry. This helps keep liquid products inside the containers and free from leaks and contamination while ensuring their freshness.

Vacuum Packaging Machinery

A vacuum sealing machine is used to extract air from a package before sealing it, increasing the shelf life of meat, dairy, vegetables, and other perishables. Vacuum sealers have widespread use in food processing and also in many households.

Heat Sealing Machine

A heat-sealing machine seals laminated films and plastics by applying heat and pressure. It is widely used in snack package sealing as well as in pharmaceutical blister pack sealing.

Key Features to Consider When Choosing a Sealing Machine

Consider the following while choosing the best sealing machine for your business needs:

Type of Packaging Material

Different materials require different sealing machines. Some of them include polyethylene, polypropylene, laminated films, and even aluminum foils. Confirm that the machine is appropriate for your packaging material.

Sealing Speed and Efficiency

Large-scale production means you will need a high-speed sealing machine in order to have maximum output. For bulk sealing, automatic machines and continuous band sealers are the best.

Size and Portability of the Machine

Select a machine by your workspace and operational requirements. Compact tabletop models are best suitable for small businesses while industrial-grade machines are best for high-volume operations.

Control Options And Automation Features

Sealing machines have automation options like temperature control, pressure regulation, and digital displays nowadays. Sealed machine control helps save on labor expenses and improve consistency.

Machine Robustness and Maintenance

A good investment would be to purchase a machine that is robust and made of high-grade materials such as stainless steel. Furthermore, think about maintenance needs, part availability, and cleaning extend.

Applications of Sealing Machines in Different Industries

Food Industry

A sealing machine also known as a sealing machine is a device that fuses products, including plastics and metals. They are important for closing snack bags, frozen dinners, dairy foods, and vacuum-sealed meat.

Pharmaceutical Industry

In the pharmaceutical industry, sealing machines preserve the effectiveness of medicines and medical devices. Common ones used for this are induction and blister-sealing machines that are used to seal bottles and pill packets.

Cosmetics and Personal Care

Sealing machines for the cosmetic industry are applied for the packaging of creams, lotions, and liquid products. That leak-proof seal is best achieved with a heat or induction sealer.

Industrial And Chemical Packaging

Filling positioning and sealing machines have to be sure that all chemical substances are being filled in super quantity and further that these are being sealed hermetically also.

Top Sealing Machine Brands and Where to Buy

Some companies make top-notch sealing machines, such as:

Creature Industry: Provides premium packaging machinery alongside offering a 10% discount on purchases.

Bosch Packaging: Renowned for industrial sealing machines.

Hualian Machinery: Service provider for vacuum sealers and continuous band sealers.

For buyers who want to invest in high-grade sealing machines, the Creature Industry assures unmatched quality at reasonable prices.

Benefits of Induction Sealing Machine

Safety is a priority and with induction sealing, we make sure the product is safe and secure. Whether it’s medicine, tasty beverages, or delicious food, we’re then to secure it all. Induction sealing is an important part of a product. In package designing, it’s one of the most important parts. An induction sealing machine is used to secure the bottle’s content from tampering, leakage, dragged newness, a longer shelf-life, and theft evidence.

1. Prevents pilferage: You cannot tamper with the seal since it defects evidence of tampering. So, it can prevent pilferage.

2. Prevents leakage: Since it results in a hermetic seal, there is no leakage. This can support businesses improve their profits.

3. Increases Shelf life: Since the product does not come in contact with air, it can maintain its freshness for a long time.

4. Assures the end user: There is a vision of assurance in this since customers know that they can get fresh products even if it is lying on the shelves for months. A sealed product is usually smelled to be hygienic and safe for consumption.

Conclusion

Investing in the right kind of sealer can help take your packaging process to the next level, making safeties of your product better and overall making your business run more smoothly. Whether you need an impulse sealer for small-scale packaging or an advanced automatic machine for large-scale production, choosing the best sealing machine tailored to your needs is crucial.

Reviews

There are no reviews yet.