Description

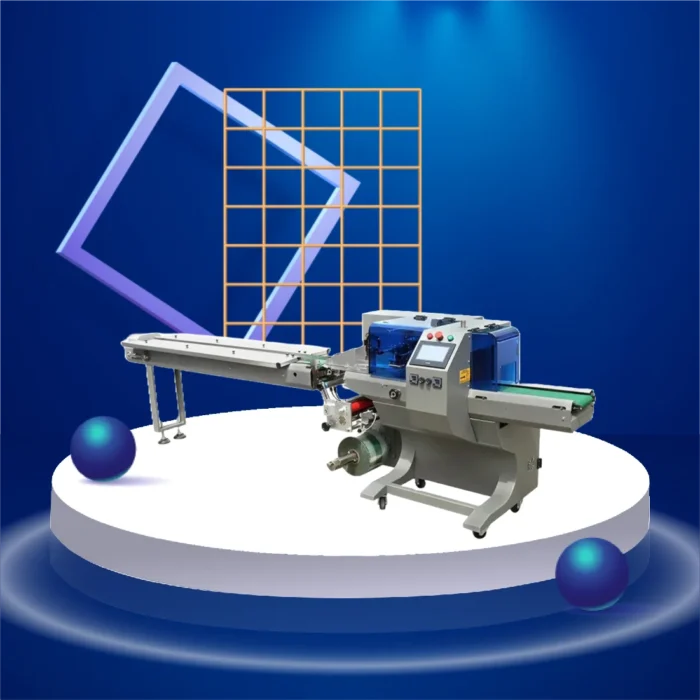

A flow wrap machine works semi-automatically to wrap products with a flexible film on a flow basis. This machine produces a package that is sealed on 3 sides which makes it possible for the items to be sealed and protected from external factors while improving the visibility of the packed product. These machines are very flexible in operation, as they can work with food products, medical products, hardware supplies, and many others.

Key Components of a Flow Wrap Packing Machine

To get a grasp of the flow wrap machine functions, it is important to understand its key features.

Feeding System: Orients and moves items to the packing area.

Forming Collar: Conforms the film to the shape of the product.

Sealing Jaws: Heat seals the film edges to complete the package. Cutting System – Cuts the roll of film into single pieces.

Control Panel: Permits the operator to define and change machine settings.

How Does a Flow Wrap Packing Machine Work?

The operation of a flow wrap machine follows a systematic process:

Product Loading: The items are being loaded onto the conveyor belt.

Film Feeding: The film is unwound from the roll and passes through the forming collar.

Wrapping: The film is placed over the product and is lengthwise sealed. Sealing and Cutting: The transverse sealing jaws of the machine seal and cut the individual packs. Final Output: The completed products are discharged to be processed or packed further.

Flow Wrap Packing Machine Price Range

The price range of a Flow Wrap Packing Machine in India varies based on features, capacity, and brand. Generally, these machines cost between ₹1,50,000 to ₹10,00,000. Basic models with manual adjustments are on the lower end, while fully automatic machines with advanced features like servo control and PLC touchscreens fall on the higher side. Companies that make things like food, drugs, and everyday consumer goods use those machines to package things well. Packing machines help speed things up and make a lot of packaging work faster and smoother. If you’re looking for reliable options, consider Creature Industry, which offers a 10% discount on purchases.

Types of Flow Wrap Packing Machines

The different kinds of flow wrap machines are classified according to their specific usage:

1. Fully Automated Flow Wrap Packing Machine

Complete operational automation

Makes use of high-speed production lines

Minimizes manual help and cuts down on cost

2. Semi-Automated Flow Wrap Packing Machine

Involves a degree of manual nourishment of products.

Useful for small and medium-sized companies

Less expensive than fully automated systems.

3. Horizontal Flow Wrap Machine

For long and flat items: biscuits, chocolates, and medical syringes.

Packaging that need to be airtight and sightly.

4. Vertical Flow Wrap Machine

Applicable to goods that do not have regular shapes

Packaging in snack and confectionery industries

Advantages of Using a Flow Wrap Packing Machine

1. Increased Efficiency

The use of the flow wrap packing machine boosts productivity rate because it mechanizes the packaging procedure, minimizing human efforts, and increasing speed of the process.

2. Cost-Effective Packaging Solution

Through automation, the packing procedure is done with the least possible materials, cutting down on labor expenses, and mistakes in packaging are no longer a problem.

3. Enhanced Product Protection

Secure wrapping provides a barrier to prevent contamination, increases shelf life, and protects products from damage during shipping.

4. Versatility in Packaging

Flow wrap machines are suitable for packaging products without differentiating them whether they are big or small, thus they are perfect for different business sectors.

5. Improved Aesthetic Appeal

With the improved accuracy and symmetry in wrapping, the packaged products are bound to please consumers’ eyes more than before.

Industries That Benefit from Flow Wrap Packing Machines

1. Food Industry

Bakery products (cookies, biscuits, bread)

Confectionery items (chocolates, candies, energy bars)

Fresh and frozen foods

2. Pharmaceutical Industry

Medical devices (syringes, bandages)

Medicine blister packs

Surgical tools

3. Consumer Goods Industry

Stationery items (pens, notebooks)

Electronic accessories (chargers, USB cables)

Household items

Choosing the Right Flow Wrap Machine

The choice of flow wrap machine selection is based on these main components:

Product Type: Examine the product’s dimensions, form, and composition. Production

Speed: Establish the speed at which the product must be packaged to meet the market demand.

Budget: Evaluate the machine’s pricing against the features it offers.

Machine Flexibility: Consider machines that offer versatility in product and packaging type.

Ease of Maintenance: Choose a machine that is maintainable easily and has a simple interface.

Maintenance and Troubleshooting Tips

Frequent Maintenance Habits

Wash cutting blades and sealing jaws regularly.

Moving components require lubrication for maintenance.

Maintain appropriate wrapping by regulating film tension.

Sensors and electrical connections ought to be checked from time to time.

The frequent problems and remedies are stated below:

Low-Quality Sealing: Change the temperature level along with the sealing pressure.

The Film Jams: Ensure that the film is appropriately aligned and set to the right tension.

Uncontrollable Cutting: Change the blades as the current ones have reached their useful life cycle.

Machine Turns Off: Look for sensor issues like faulty parts or incorrect product positioning.

Conclusion

A flow wrap packing machine is an indispensable tool in modern packaging, offering efficiency, product protection, and cost savings. From food production to pharmaceutical and consumer goods companies, integrating them into their lines can make things flow much better. Nothing beats the efficiency and productivity gains that technology, especially the right kind of machines, brings. By selecting the right machine, maintaining it properly, and optimizing its performance, companies can enhance productivity and product quality.

Reviews

There are no reviews yet.