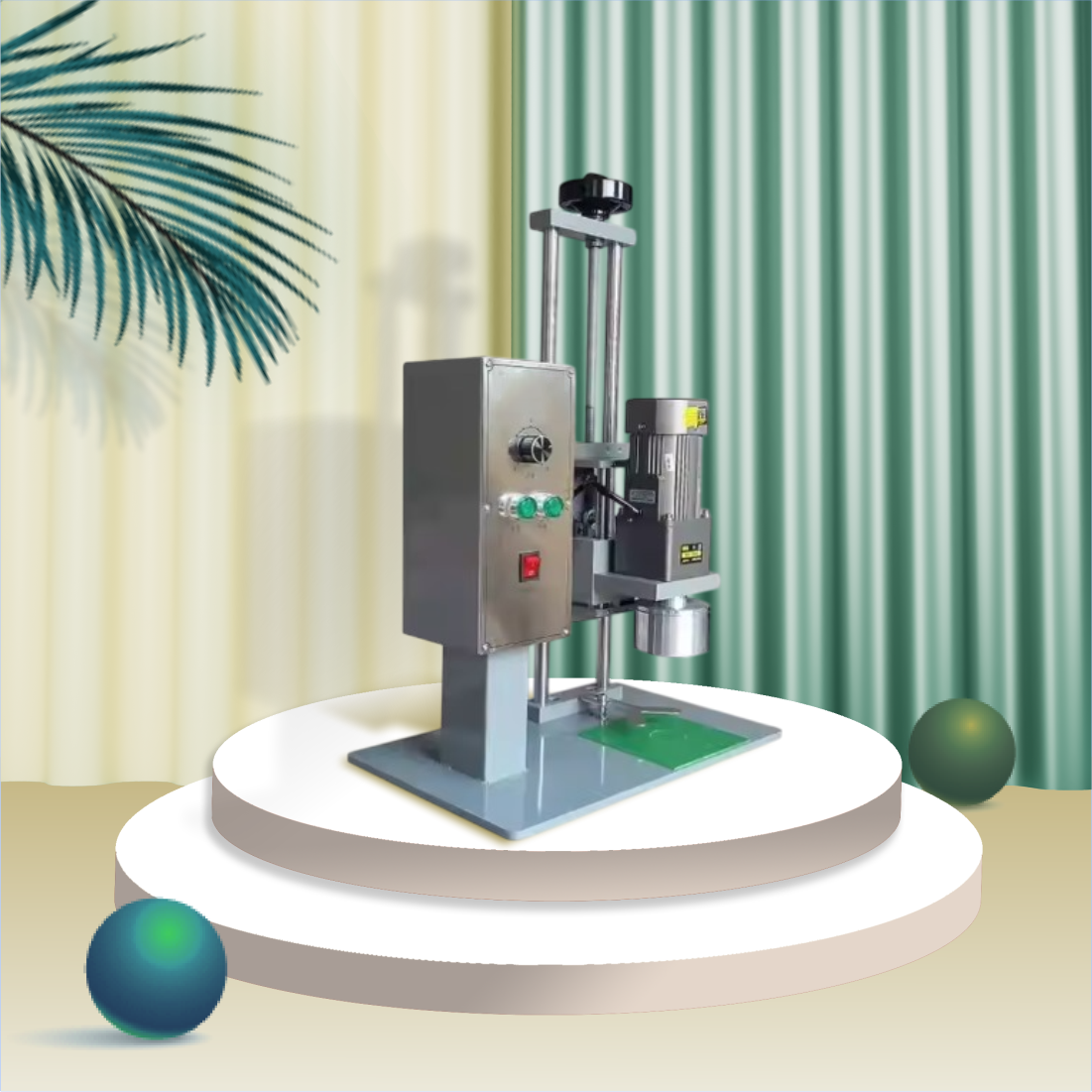

Bottle Capping Machine

₹30,000

| Name | Bottle Capping Machines |

| Brand | Creature Industry |

| Packaging Type | Plastic Bottles |

| Grade | Automatic |

| Voltage | 220v,50hz |

| Power | 0.12kw |

| Dimension(l*w*h) | 1000*800*1200mm |

| Turntable Diameter | 800mm |

| Suit Bottle Diameter | 40-130mm(customized) |

| Suit Bottle Height | 30-200mm(customized) |

| Warranty | 1 Year |

| Capacity | 60pcs/min |

| Moq | 1set |

| I Deal In | New Only |

| Country Of Origin | Made In India |

| Price Range | ₹30000 – ₹300000 |

A bottle capping machine is a specialized machine used in a number of industries to firmly fasten the bottles with caps or closures. These units are of strong interest for product safety, leakage prevention, and containment assurance. They have been found to possess a general versatility for drinks, pharmaceuticals, cosmetics, and chemicals.

Automated, semiautomated, and fully automated automation levels of bottle capper machines are available. The basic manual operation is coincident to manual control, while automated machines permitone to perform the capping procedures more quickly, in a high coming and economical way. They are capable of handling different bottleneck types (screwpins, snap caps, or corks) according to the need of the bottle and the industry norm.

Key Features of Bottle Capping Machines

Modern bottle capping machines come with advanced features to meet diverse industry needs. Here are the top features to consider:

Adjustable Speed

Variable speed controls are the vast majority of the machines that are available to respond to the requirements of the production process in your plant, with no jerky run nor loss of quality.

Versatility

Highly flexible to be powered on bottles having various shapes and fitted with different kinds of caps (when they exist), a bottle cap machine can be highly versatile and can be exploited in a wide range of different sectors (water bottles, cosmetics bottles and drugs or the like).

High Precision and Consistency

These devices will allow very accurate and even cappings that allow minimal contaminations and product leakage.

Durable Construction

For example, the robustness of the industrial environment can be guaranteed by the use of strong materials, e.g., stainless steel, etc.

Ease of Operation

These machines are simple to operate with minimal time preparation and are commercially available, however, they are being used in medium-sized practices.

Compact Design

They are space-efficient shapes, so they follow very naturally for production facilities with limited production space.

Bottle Capping Machine Price Overview

The cost of a bottle capping machine is dependent not only on the size of the machine but also on the quantity and nature of production and the level of automation. There might be an affordable entry point even for entry-level machines, with a very expensive option for high-end/feature-rich industrial machines. In setting price, it should be taken into account how long-run labor cost savings and better efficiency can be achieved.

Type of Bottle Capping Machine

Here are 5 types of bottle capping machine

- Automatic Capping Machine

- Semi-Automatic Capping Machine

- Chuck Capping Machine

- Spindle Capping Machine

- ROPP Capping Machine (Roll-On Pilfer Proof)

Why Invest in a Bottle Capping Machine?

Without a doubt, a bottle capping machine is a must-have for most operators in the beverage sector. Some fundamental benefits include:

High-Speed Capping: Extremely suitable for factory production lines.

Hygiene Sealing: Guarantees the contamination-free capping of water bottles.

Energy Efficiency: constructed for efficiency which reduces the running costs.

Conclusion

Whether you’re exploring a bottle capping machine price for a startup or upgrading to a high-capacity water bottle capping machine, choosing the right equipment is crucial. Look for features that align with your business goals to enhance productivity, maintain product quality, and ensure customer satisfaction.

Top FAQS About Bottle Capping Machine

What is a bottle capping machine, and how does it work?

A bottle capping machine is a device used to furnish caps/lids to bottles. It confirms that the caps can be clamped quite tightly in a manner that will contain the product inside a single continuum. This is achieved by bringing the cap into contact with the bottle, by applying a force, and then clamping it so that it is torque or threaded, depending on the design of the cap.

Which machine is used for the sealing of bottles?

A bottle sealing machine (also known as a bottle capping machine), is a machine that securely completes the seals of bottles with caps or lids. It ensures good tightness in a variety of applications (drinks, pharmaceuticals, cosmetics, etc) to prevent leakage and contamination.

Do you offer warranties and after-sales services for your machines?

Yes, all our machines come with a warranty covering manufacturing defects. We also provide excellent after-sales support, including spare parts, maintenance services, and technical assistance.

Do you provide technical support and training for using the machines?

Yes! We offer technical support and training to help you get started. Our team ensures you understand the machine’s operation, troubleshooting methods, and maintenance procedures.

Can these machines be customized for specific production requirements?

We take into account certain elements, including the size of the container, the type of closure, and the rate of production needed, and we accommodate your preferences for the machine adjustments. Our specialists will be in contact with you in order to come up with the best possible machine.

Related products

-

Shrink Tunnel Machine

₹40,000 -

Impulse Hand Sealer

₹1,999 -

English

English

Reviews

There are no reviews yet.