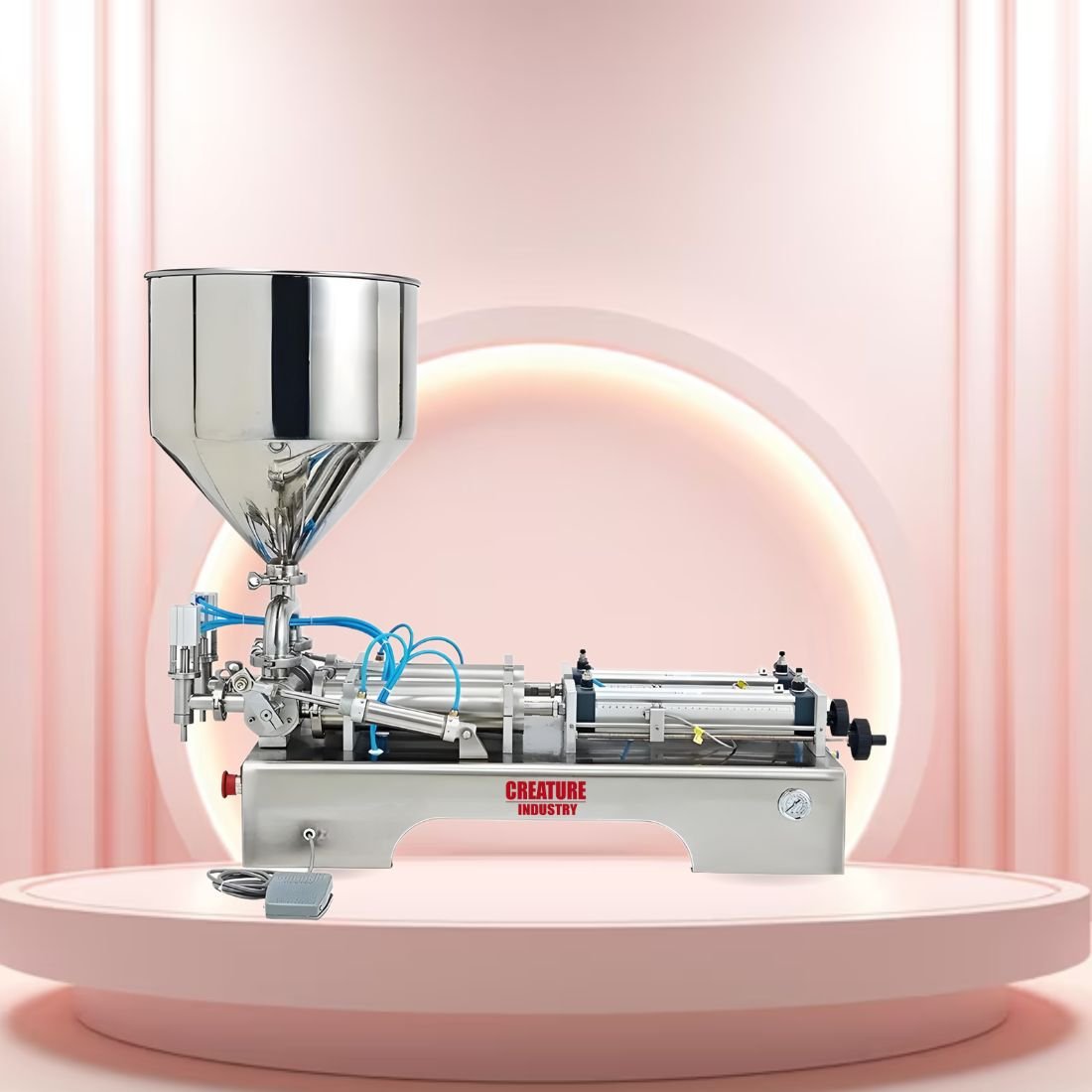

Automatic Paste Filling Machine

₹17,000

Specification

- 5-25 Bottles/min

- Application: Milk, Water, Oil, Juice, Liquid

- 0.5 kW

- Stainless Steel

- Semi-automatic

- 5 KG

- Made in India

Price Range – ₹17000 to ₹55000

Nonetheless, expediency and accuracy are anything but a small matter in a fluctuating manufacturing world. The automatic paste filling machine has turned out to be the revolution of the packaging industry and provides novel applications for the improvement of productivity as well as the adaptation of a constantly increasing of sophisticated packaging demand. From the point of view of its automation, this equipment is transforming the manufacturing process of paste products by achieving a higher production speed, higher accuracy and a lower cost of labor.

What is an Automatic Paste Filling Machine?

The term automatic paste filling refers to the modern industrial machinery used to fill containers, jars, tubes, and different types of packaging with pasty and highly viscous fluids. This modern technology finds application in a number of industries, such as chemical, pharmaceutical, cosmetics, food, and beverage. Compared to the manual filling method, which is extremely time-consuming and has a high risk of human error, the automatic paste filling machine improves both the speed and the accuracy of filling.

The machine is usually operated by combine the action of the piston and the pumping system, which allows the machine to dispense exact amounts of substances each time the machine is activated. Such machines are user-friendly as the only requirements are to set the machines’ bones parameters, such as volumetric fill amounts and filling speed.

Key Features of Paste Filling Machine

Automatic paste filling machines come with a host of features designed to improve the efficiency and productivity of manufacturing processes. Some of the key features include:

Automatic paste filling machines come with a wide range of features that improve the efficiency and productivity of manufacturing operations. Some of these features are:

High Precision and Accuracy

Perhaps the greatest strength of paste filling machines is the high degree of accuracy with which containers are filled. Sophisticated control systems and sensors monitor and regulate the supply of paste to ensure each container gets an exact amount; this assures product quality and minimizes waste.

Adjustable Filling Volume

Most machines have adjustable filling volumes, which provide the manufacturer an easy method to change between the various product and packaging shapes and sizes. Whether the requirement is small jars or large containers, the machine can be set to dispense the appropriate volume of paste for each product.

Flexibility in Types of Packaging

Automatic paste filling machines are not restricted to a specific type of packaging only. They can manage a range of containers such as bottles, tubes, jars, and pouches. Because of this capability, they are advantageous to industries that need to deal with multiple product packaging types.

Technological Innovation in Hygiene

Hygiene is crucial, especially in the food and the pharmaceutical industry. These automatic filling machines with paste are built with parts that can be easily cleaned, thus making them suitable for industries that deal with sensitive hygiene products. They are constructed with stainless steel and are designed and equipped with features like CIP (clean-in-place) systems for sanitation.

High-Speed Operation

With automated systems in place, paste filling machines can operate at significantly faster speeds compared to manual filling methods. This high-speed operation leads to increased production rates, ultimately helping businesses meet high demand without compromising on quality.

Applications of Paste Filling Machines

With their general use of automatic paste filling machines it is feasible to apply the machines to the widest possible extent of industries. Below are some of the most common applications:

Food and Beverage Industry

The food industry is one of the top products of automatic paste filling equipment. The goal of these . devices is to put things (e.g., sauces, jams, spreads, syrups) into jars, bottles, and pouches. Due to the high viscosity usually encountered with food products, such devices are also employed with viscous liquids.

Cosmetics and Personal Care

Automatic paste filling machines are employed in the production of personal care (creams, gels, lotions, and pastes) in the cosmetic industry. Viscosity and thickness are the defining quality attributes and repeated qualitative factors in the formulation of cosmetic products.

Pharmaceuticals

In an aseptic environment, the pharmaceutical factory employs auto paste filling machines for filling ointment, cream, and other medicinal pastes. This is just one of the key roles that ensure the quality of, e.g., highly consumable consumables about devices is also present while strictly adhering to regulations.

Chemicals and Lubricants

In the chemical and automotive industries’ filling of chemicals and products, traditional paste filling machines with automatic operation for filling the containers of lubricants and adhesives, etc., have been employed. With the help of selectively defined filling processes, only the required amount of the product can be dispensed consequently and thereby the error rate and product loss are minimized.

Advantages of Using Automatic Paste Filling Machines

Installation of automatic paste filling machines yields many benefits, including:

Increased Efficiency

Automation of the filling process in the manufacturing industry can provide production increased in a short span of time, but with a very high accuracy is maintained. Consequently, a faster turnaround and increased throughput can be realized.

Consistent Quality

Automated systems reduce the risk of human error and as a consequence an improved quality product is achieved. As all containers have the same capacity, the batches are the same.

Cost Savings

Although the system for an automatic paste dispensing machine requires expensive setup, its operational cost is very, very high. Using these machines the labor work and the cost associated to it get decreased as does the output (production) get increased. In addition, due to their efficacy and accuracy, minimises waste (ie, cost), which, at the same time, results in economic benefits.

Enhanced Hygiene and Safety

Automatic paste filling machines have been designed under the hypothesis of contamination, i.e. Simplicity of cleanup and automatic filling results in negligible risk of contamination, a crucial factor for the food and pharma industries, for example. Machines not only improve workplace safety but also empower the use of potentially hot or dangerous work/material manipulations.

Customization and Scalability

There is an option for producers to tailor paste filling machines to individual production needs. These machines are adapted in an adaptable manner, e.g., by the rate of the filling, size of the container, or viscosity of the paste, e.g. Also, the number of machines on the production line can be expanded for companies by combining more and more machines as the production volume increases.

Conclusion

The automatic paste filling machine is a powerful tool for businesses looking to streamline their production processes, improve efficiency, and maintain high-quality standards. By automating the paste filling process, manufacturers can significantly reduce labor costs, minimize product waste, and ensure consistent product quality. With a wide range of applications across various industries, the paste filling machine is becoming an indispensable asset for modern manufacturing.

1 review for Automatic Paste Filling Machine

Related products

-

Liquid Filling Machine

₹55,000 -

Auger Filling Machine

₹180,000Original price was: ₹180,000.₹150,000Current price is: ₹150,000. -

Shrink Tunnel Machine

₹40,000

English

English

Ram singh tomar –

Achi speed hain