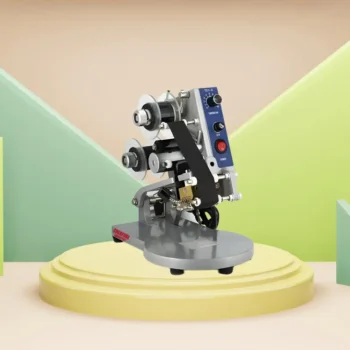

Description

The MS Solid Ink Coding Machine is a compact batch coding system that is a high-performance maker for barcodes, expiration dates, MRP, bid dates, list, and other essential information. It is one of the most trusted and reliable printing devices owing to the solid ink rollers used in making the print. These rollers melt on contact and dry instantly on laminated pouches, plastic bags, cartons, labels, foils, and paper boxes. It is best suited for the food, pharmaceuticals, cosmetics, FMCG, and electronics industries. This machine is a solution to problems pertaining to modern high-speed production lines and business compliance with regulatory labelling standards.

Advantages

1. Instant Drying and Smudge-Free Printing Every print made with solid ink technology is instantly dry, smudge-proof and permanent which is well suited for fast production lines.

2. High-Speed Performance The MS solid ink coder prints up to 300 prints per minute making it ideal for bulk packaging operations that require high throughput while maintaining print quality.

3. Low Operational Cost Because solid ink rolls contain thousands of prints worth of printing, operational costs are lower and waste is reduced. The absence of liquid ink eliminates the need for it altogether, reducing mess and maintenance.

4. Easy to Operate Adjustments to print settings, temperature, and speed can be made easily through manual and automatic feeding systems. It also allows multi-line printing with varied font sizes.

Main Characteristics of MS Solid Ink Coding Machine

Supports the printing of laminated pouches, labels, paper, BOPP, and even aluminium foil.

Temperature control system ensures thermal-based ink transfer achieves best results.

Designated robust steel frame ensures operation free from vibrations.

Motor noise and precision grade are both low.

Solid ink roller offers a long-life span for precision printing.

Manual operation and conveyor belt options available.

Design is compact and portable.

Units offered in vertical, horizontal, and inline configurations.

MS Solid Ink Coding Machine – Key Features

Solid Ink Technology Uses solid ink rollers for high-speed printing that is fast-drying, smudge-proof, and provides vivid contrast.

Clear and Permanent Coding Batch numbers, manufacturing dates, expiry dates, and pricing information can be printed on packaging materials with clarity.

High-Speed Operation Maintains quality while fast printing on pouches, cartons, laminates and labels.

Temperature and Speed Settings Adjustable Set markers for material type and ink requirements.

Sturdy MS Body Industrial mild steel (MS) casing makes the machine durable whilst preserving portability for long term use.

Easy to Use and Maintain Operation simplicity stems from the direct control interface right down to the quick-change ink roller system.

Multi-Language Support Depending on setup, prints can be made in English, Hindi, or other regional languages.

Conclusion

The MS Solid Ink Coding Machine is a must have for any business that is in the product packaging and labelling field. What it brings to the table is low cost operation, high speed performance, and professional print quality which in turn makes it a smart purchase for maintenance of compliance and building customer trust via clear and consistent coding. Also in the food manufacturing, pharmaceutical and hotel based food packaging industries this machine is your solution for getting your products to market with clear identification and batch info.

Reviews

There are no reviews yet.