Description

A shrink tunnel machine is one of the most commonly used industrial machinery in various industries, primarily for professional packaging purposes. This machine enhances the presentation of products by using heat to apply durable seals around plastic films. In this guide, we will discuss and analyze the operating mechanism, advantages, areas of application, and important factors when choosing the right shrink tunnel machine for your company’s needs.

How Does a Shrink Tunnel Machine Work?

A shrink tunnel machine uses a concept that is simple yet very effective. The steps needed are:

Placing The Product – The product is encapsulated with a shrink film of PVC, polyolefin, or polyethylene.

Heating – The wrapped product is put inside the tunnel with hot air circulation.

Film Reduction – As a result of heat, the shrink film contracts and tightly wraps around the item.

Cooling Down & Completion – The item is sealed in and exits the tunnel to cool down and finish.

Key Feature Of Shrink Tunnel Machine

- Perfect and even shrink wrapping throughout the surface.

- The conveyor speed can be easily adjusted to cater to different packing requirements.

- It is an energy-efficient insulator for low energy Ability to work with various types of shrink film.

- Strong construction with straightforward controls for convenient maintenance and use.

Applications of Shrink Tunnel Machine

Shrink tunnel machines, it seems, are being used for an increasingly diverse set of industrial uses, such as packaging, sealing, and goods safeguarding. Here are five key applications of shrink tunnel machines:

Food Packaging: Shrink tunnel machines have been widely used in the food industry for wrapping, bottles and cans but also trays containing food products. The machine performs a heat shrink to tightly clamp the plastic sheet to the product, and in addition features a high seal preventing senescence and, to a great extent, contamination.

Bottling and Canning: Shrink tunnels are used in the beverage sector to reduce the size of polyethylene or glass bottles and cans. It provides product protection and in the very same way also provides very good, transparent tamper-evident packaging.

Electronics and Consumer Goods: Shrink tunnel machines are also protective enclosures for electronic products and consumer goods, providing cushioning and dust and moisture protection and acting as a shock absorber during storage and transportation.

Pharmaceuticals: Shrink tunnels are used in the context of sold items medicine containers [e.g., bottles, blister packs], and so on drugs in the pharmaceutical sector. Shrink-wrapped packaging helps ensure product integrity and prevents tampering.

Retail Packaging: Shrink tunnel machines are commonly used for pack filling of multi-packs in retail. For example, an unpackaged shrink-wrapped single-unit package of cans or bottles is arguably one of the most common goods on a store shelf. Shrink film offers a finished, neat appearance, and cargo protection while shipping and storage.

Types of Shrink Tunnel Machines

Hot Air Shrink Tunnel Machine

Uses hot air to circulate and shrink the films. It is suitable for light products that are also sensitive to temperature.

Steam Shrink Tunnel Machine

Uses steam in place of hot air, which is great for polyolefin and PVC shrink films. It is a common method for shrinking labels in beverages.

Infrared Shrink Tunnel Machine

Uses infrared radiation to provide evenly distributed heat. Delicate and energy-saving devices that are great for delicate products.

High-Speed Shrink Tunnel Machine

For bigger industries focused on mass production. Comes with heavy-duty heating devices and strong conveyor belts that work at high speeds.

The Advantages of a Shrink Tunnel Machine

Improved Product Security

Dust, moisture, and other elements can damage products, but shrink tunnel machines offer a tight seal that ensures proper protection.

Affordable Packaging Option

Unlike other traditional packaging materials, shrink wrap is more affordable, making it a cost-effective option for businesses.

Enhanced Visual Look

Products are presented elegantly due to the aesthetic appeal brought forth by wrapping, thus increasing professionalism.

Flexible and Compatible

These machines offered greater flexibility in terms of packaging due to their compatibility with a variety of product sizes and types.

Green Packaging Option

Shrink films being highly recyclable and biodegradable makes them eco-friendly sustainable initiatives.

How to Choose a Suitable Shrink Tunnel Machine

Some things to keep in mind when buying a shrink tunnel machine are: Machine size and Product type and material – Select a machine that fits both the size and material type of your product. Production speed – If your production line is a high-production one, go for high-speed shrink tunnel machines. Operating costs – Select models that are more energy efficient to lower your costs. ROI and Budget – Be mindful of how beneficial the machines are. It is also important to consider how much ROI you make on the purchase. Maintenance costs – If a machine has a frame made out of stainless steel or other durable metal, it will most likely be reliable and last longer.

Shrink Tunnel Machine Price Range

The cost of a downgraded tunnel machine is prevented by its expansion, features, and capacity. Low-cost cut-back mini tunnel machines are available for those who are looking for cheaper options. Manufacturers provide quite a few options suited to different business needs if you’re looking for the lowest price of a decreased tunnel machine in India. In India Shrink Wrap machines are available at various prices which fit different business needs and budget constraints. Typically, the price is determined by constraints like the size of the machine, its speed, degree of automation, and additional features.

The cost of simple models manufactured for small businesses ranges from Rs.50,000 – Rs.100,000. Alternatively, machine type, mid-range, with a couple of other novelties and medium speed is priced between ₹1,00,000 – three,00,000. According to adaptation and demand, for industry applications with high throughput, high-speed, and high-volume, high-end Shrink Wrap machines may also involve the operation cost of up to ₹3,0,00,000 (including both adaptation and demand) based on the consideration of the industry application, and up to ₹10,00,000 respectively.

Shrink Tunnel Machine Spare Parts and Maintenance

You’ll need to ensure that a wide variety of components are included to limit downtime as required making sure of optimal performance. For the wrapping shrink machine to work efficiently, it is necessary to acquire necessary parts from trusted suppliers that conglomerate original products.

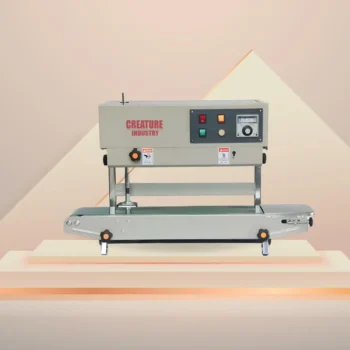

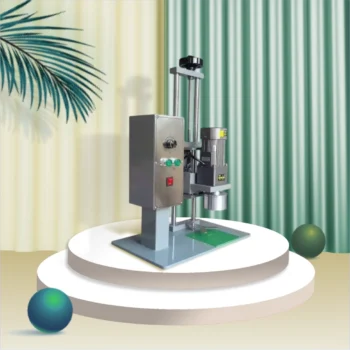

Top Manufacturers of Shrink Tunnel Machines in India

Creature Industries Is one of the few countries in the world that can claim to be a machine manufacturer, primarily specializing in shrink tunnel machines. Contrary to its competition, Creature Industries delivers machines regardless of the budget whether it’s a mini shrink tunnel or a bigger edition. Cozy up with Creature Industries today and experience the dependability that has made us the preferred choice within the industry.

Conclusion

Investing in a shrink tunnel machine is useful, especially for businesses that wish to improve their packaging techniques. This is important as it makes you understand the costs related to reduced wrap machines and how best to choose a manufacturer, whether you are looking for premium fashions or more cost-effective options.

Reviews

There are no reviews yet.