Description

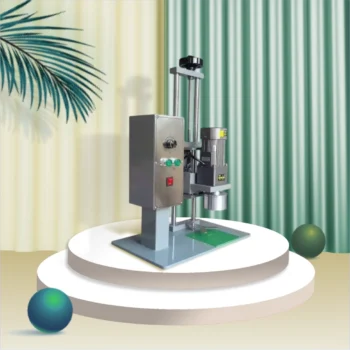

A mild steel band sealer is a machine used in packaging applications to seal bags or pouches using a continuous band of stainless steel. It is commonly used in industries such as food, pharmaceuticals, chemicals, and other manufacturing sectors.

It’s worth noting that while mild steel band sealers are commonly used, there are other types of band sealers available, such as those made from aluminum or plastic materials. Mild steel is a carbon steel with low carbon content, making it less prone to corrosion compared to other types of steel.

Key Features of MS Band Sealer:

- Efficient Sealing: The MS Band Sealer provides strong and reliable sealing for a wide range of materials, including polyethylene, polypropylene, and other packaging films, ensuring the security of products.

- Temperature Control: Equipped with precise temperature control, it allows for consistent sealing performance, avoiding overheating or underheating that could damage the product or packaging.

- Adjustable Band Width: The band width is adjustable, making it versatile and able to handle different sizes of packaging and sealing requirements.

- Compact and Durable Design: Built with a robust metal frame, the MS Band Sealer is designed to withstand heavy-duty use, making it perfect for industrial environments.

- User-friendly Operation: It features easy-to-operate controls, making it suitable for both beginners and experienced users.

- Speed and Productivity: With high-speed sealing capabilities, the MS Band Sealer enhances productivity, making it ideal for large-scale packaging operations.

- Energy Efficient: The machine consumes less power during operation, offering cost-saving benefits in the long run.

- Safety Features: It includes built-in safety mechanisms such as automatic shut-off and thermal protection to prevent accidents during operation.

- Versatility: Capable of sealing a variety of pouch types, including stand-up pouches, zipper bags, and other flexible packaging formats.

- Low Maintenance: The MS Band Sealer requires minimal maintenance, ensuring long-term operation with little downtime.

These features combine to make the MS Band Sealer a reliable and efficient choice for industrial and commercial packaging needs.

Applications of MS Band Sealer

Food Packaging: Seal out of the box solutions for spice, tea, coffee, snacks, grains, flour, dry fruits.

Pharmaceutical Products: we seal medical packaging materials, tablets, powders, supplements.

Chemical Products: we use these for packaging pesticides, fertilizers, detergents, and also a host of other products.

Retail and Wholesale: our packaging solutions are used in a broad range from general merchandise to the needs of kirana stores and supermarkets.

Reviews

There are no reviews yet.