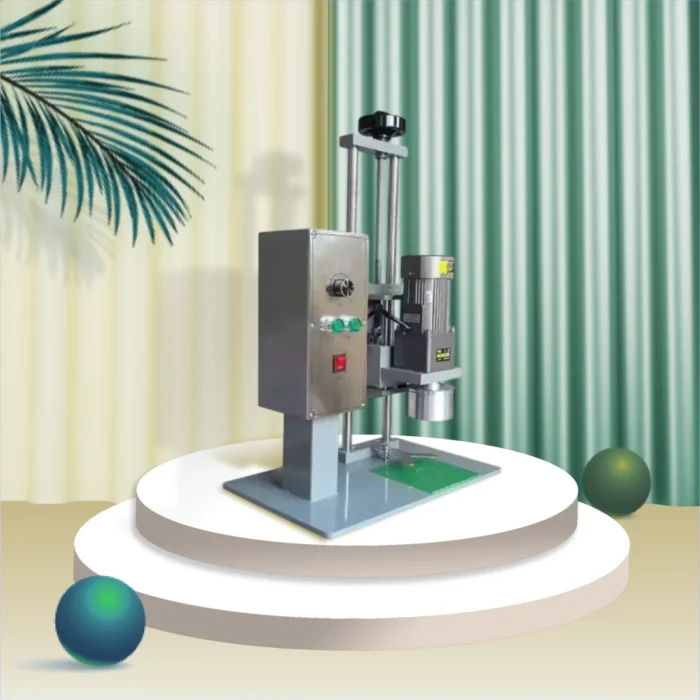

Description

We are a dependable Bottle Sealing Machine company that provides very advanced and efficient sealing solutions for a large variety of industries, which include food and beverage, pharmaceuticals, cosmetics, and chemicals. The machines we have developed present tight, secure, and consistent seals, which in turn ensure product safety and longer shelf life.

Applications of the Bottle Sealing Machine

Food & Beverage Industry:- Bottle sealing machines are used for water, soft drinks, juice, milk, sauce, oil, and other liquid food products.

Pharmaceutical Industry:- We also see them used in the pharmaceutical industry for medicine, syrups, tablets, capsules, and chemical solutions. Secure sealing here is for product safety, hygiene, and also to meet industry standards.

Cosmetics & Personal Care Industry:- These machines are often used for sealing bottles of shampoo, lotion, cream, perfume, hair oil, and other skincare products. Well-made seals improve the look of the product and prevent spillage during shipping.

Chemical Industry:- Bottle sealing machines are perfect for sealing containers with chemicals, solvents, pesticides, lubricants, and cleaning liquids. Secure sealing ensures safe storage and handling.

Key Features of Our Bottle Sealing Machines

Sealing with high precision and speed. Secure and sturdy construction. Simple operation and maintenance. Efficient energy consumption Ideal for small, medium, and large-scale production

Benefits of the bottle sealing machine

1. Leak-Free and Secure Sealing:- Bottle capping machines which do strong and consistent seal, which in turn prevents leakage and protects products in storage and transport.

2. Enhanced Product Safety and Hygiene:- Automated sealing reduces human contact, which in turn reduces the risk of contamination. This is particularly true for food, beverage, and pharmaceutical products.

3. Increased Production Efficiency:- Using a bottle capping machine greatly increases speed, which is in comparison to manual methods, which in turn helps manufacturers to achieve high production output.

4. Consistent Sealing Quality:- The machine seals all bottles the same, which in turn maintains consistent quality and professional appearance

How a Bottle Sealing Machine Works

Positioning Bottles Bottles are filled, then positioned either manually or automatically under the sealing head on the conveyor belt. Placement of Caps: A cap feeder can automate the supply of caps. Otherwise, caps can be placed manually on the bottle. Aligning the Bottles The bottle is mechanically guided to the correct position to avoid damage and ensure sealing. Sealing Process In the case of induction sealing machines, electromagnetic heat is used to seal the foil liner to the cap. In capping or screw sealing machines, rotating heads are used to tighten the cap. In ROPP sealing machines, the aluminum cap is locked to the neck of the bottle by rollers.

Our Price Range of Bottle Sealing Machines

Here is a standard pricing breakdown for various types of bottle capping machines, which we recommend for use in your product information and sales materials (prices are approximate and will vary by model, feature, and brand).

Machine Type Typical Price Range

Handy / Manual ~₹5,000 – ₹10,000

Semi-Automatic ~₹15,000 – ₹80,000

Automatic (Industrial) ~₹75,000 – ₹750,000+

Maintenance of the Bottle Sealing Machine

Daily Maintenance:- At the end of each shift, wipe down the sealing head and contact parts. Remove dust, oil, and product remnants from the surface of the machine. Test the power supply, switches, and emergency stop button. Look over the caps and bottles to make sure there are no contaminants.

Weekly Maintenance:- As instructed by the manufacturer, apply lubricant to the various moving components, including the chains, gears, and bearings. Check the alignment and tension of the conveyor. Check the sealing head, sealing rollers, or induction coil for signs of wear. Inspect and tighten any loose fasteners, bolts, and nuts

Monthly Maintenance:- Check out the motor, gearbox, and electrical wiring for any unusual noise or heat. Check torque settings and seal pressure accuracy. Check sensors and control panels for proper function. Replace as required worn-out rubber components, springs, or seals.

Summary

Advanced machines, which include food, pharma, cosmetics, and chemicals industries’ machines, we have for bottle sealing,g which do very fast, precise, and leak-proof sealing to ensure safety, hygiene, and extended shelf life. We have machines which range from manual to full automatic, which cover induction, screw, and ROPP sealing, which in turn increases production efficiency and which also maintain very consistent quality. Price range goes from ₹5,000 to ₹7,50,000+ based on the level of automation. We also do regular daily, weekly, and monthly maintenance,e which in turn ensures the machines’ durability and performance. Also, we are FSSAI compliant, which in turn supports food safety standards and regulatory requirements.

Reviews

There are no reviews yet.