Description

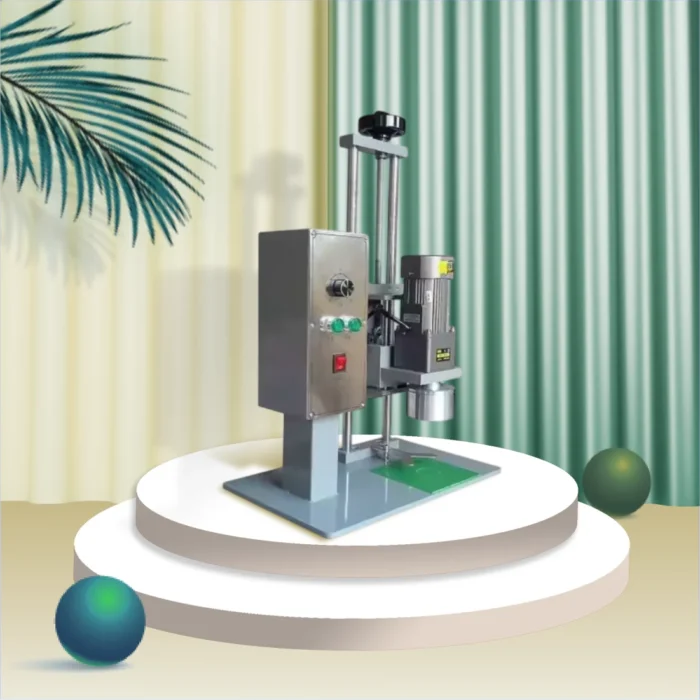

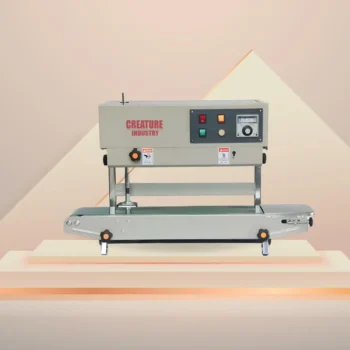

At Creature Industry we present to you our range of high quality Bottle Capping Machines which we have designed for accurate, secure and uniform sealing of all types of bottles. We have built our machines to meet the marks of today’s packaging world which includes efficiency, hygiene and long term performance for your growing business. We put emphasis on innovation, durability and easy operation which is why our machines are the perfect choice for both start ups as well as large scale manufacturing units.

A bottle capping machine is a specialized machine used in a number of industries to firmly fasten the bottles with caps or closures. These units are of strong interest for product safety, leakage prevention, and containment assurance. They have been found to possess a general versatility for drinks, pharmaceuticals, cosmetics, and chemicals.

How Our Bottle Capping Machines Work

Our Bottle Capping Machines operate through a smooth and systematic process:

Our Bottle Capping Process is as follows:

- Filled bottles are put in by hand or transferred automatically to the conveyor.

- Caps are put through a cap-feeding system or placed in by hand (which varies by model).

- The capping head applies a measured force.

- Caps are tight to the same degree to prevent leakage.

- Finished products move on to labelling or packaging.

This process is for consistent sealing, reduced waste, and high production speed.

Types of bottle capping machines we produce.

At Creature Industry, we present a full range of capping solutions.

- Manual Bottle Capping Machine

- Semi-Automatic Bottle Capping Machine

- Fully Automatic Bottle Capping Machine

- ROPP Bottle Capping Machine

- Screw Cap Capping Machine

- Pneumatic Bottle Capping Machine

Key Features of Our Bottle Capping Machines

Modern bottle capping machines come with advanced features to meet diverse industry needs. Here are the top features to consider:

Adjustable Speed

Variable speed controls are the vast majority of the machines that are available to respond to the requirements of the production process in your plant, with no jerky run nor loss of quality.

Versatility

Highly flexible to be powered on bottles having various shapes and fitted with different kinds of caps (when they exist), a bottle cap machine can be highly versatile and can be exploited in a wide range of different sectors (water bottles, cosmetics bottles and drugs or the like).

High Precision and Consistency

These devices will allow very accurate and even capping machine that allow minimal contaminations and product leakage.

Durable Construction

For example, the robustness of the industrial environment can be guaranteed by the use of strong materials, e.g., stainless steel, etc.

Ease of Operation

These machines are simple to operate with minimal time preparation and are commercially available, however, they are being used in medium-sized practices.

Compact Design

They are space-efficient shapes, so they follow very naturally for production facilities with limited production space.

Application Of Creature Industry Bottle Capping Machine

Our bottle capping machines are appropriate for:

- Drinking water and beverage production facilities.

- Syrups and liquid pharmaceuticals.

- DIBLE OILS and lubricants.

- Cosmetics and personal care items.

- Chemical products and industrial liquids.

- Ayurvedic and herbal goods.

Benefits of Using Bottle Capping Machines

Invest in a top quality bottle capping machine which brings in many operational benefits:.

✅ Higher Production Speed

✅ Improved Product Quality and Consistency

✅ Reduced Labor Costs and Errors

✅ Enhanced Hygiene and Safety

Also includes a variety of cap sizes and types.

✅ Compliance with Industry Regulations

Our Bottle Capping Machine Price Range

The price of a bottle capping machine in India varies depending on the type, automation level, capacity, and brand. Here’s a detailed price range based on current market trends:

| Type of Bottle Capping Machine | Capacity | Approx. Price Range (INR) |

|---|---|---|

| Manual Capping Machine | 10–20 bottles/min | ₹18,000 – ₹35,000 |

| Semi-Automatic Capping Machine | 20–60 bottles/min | ₹45,000 – ₹1,20,000 |

| Automatic Capping Machine | 60–200+ bottles/min | ₹1,50,000 – ₹7,00,000+ |

| ROPP Capping Machine | 50–150 bottles/min | ₹1,20,000 – ₹5,50,000 |

| Snap/Press-On Capping Machine | 40–100 bottles/min | ₹70,000 – ₹2,50,000 |

| Multi-head Rotary Capping Machine | 200–500+ bottles/min | ₹5,00,000 – ₹15,00,000+ |

Why Invest in a Bottle Capping Machine?

Without a doubt, a bottle capping machine is a must-have for most operators in the beverage sector. Some fundamental benefits include:

High-Speed Capping: Extremely suitable for factory production lines.

Hygiene Sealing: Guarantees the contamination-free capping of water bottles.

Energy Efficiency: constructed for efficiency which reduces the running costs.

Maintenance and Troubleshooting Tips

To maintain long term performance and reduce down time, we have put together these tips:.

- Regular maintenance of all machine parts, in particular the chucks and spindles.

- Lubricate as directed by the manufacturer.

- Check out for damage to belts, gears, and cap feeding systems.

- Calibrate torque settings periodically

- Keep sensors and control panels dust-free

- Train staff in safety protocols and standard operating procedures.

When you experience problems like misalignment of caps, over tightening, or machine jamming please refer to the user manual or get in touch with a professional.

Conclusion

Whether you’re exploring a bottle capping machine price for a startup or upgrading to a high-capacity water bottle capping machine, choosing the right equipment is crucial. Look for features that align with your business goals to enhance productivity, maintain product quality, and ensure customer satisfaction.

Reviews

There are no reviews yet.