Description

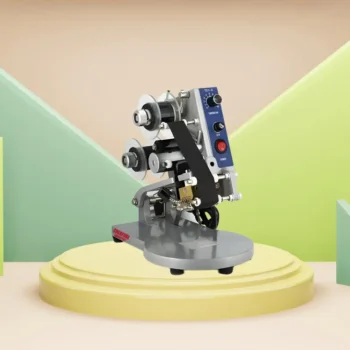

Handy Batch Coding Machine is a compact, portable, handheld batch coding machine. These machines are designed for small businesses and startups where mobility is essential. This machine is mostly used in small-scale manufacturing of food and beverages, pharmaceuticals, and cosmetics. Whereas some special features may vary depending on the model and manufacturing.

This machine is used in the packaging and manufacturing industry to print essential information on products and items such as MRP dates, expiration dates, production dates, batch numbers, and other identification marks on products or packaging materials. This information is important for tracking, inventory management, and quality control purposes.

Application

The Batch Coding Machine is extremely versatile concerning high-speed, automated coding work, etc. It has been proven to be very effective in barcoding items with their respective information, e.g., batch number, production date, or expiration date. The application is highly viable for fields like pharma, food (and cosmetics) applications where accuracy, reproducibility, and all things regulatory are well within grasp. Due to the facility, robustness, and low operational maintenance, this is an inexpensive method to enhance productivity and reduce the quality control in factories.

Features

1. Portable Design: Handy batch coding machines are generally lightweight and compact. Because of this, we can easily take and bring this machine anywhere. Due to this, we get a lot of help with the product environment.

2. Battery Operated: Many batch coding machine machines come with rechargeable batteries. Which eliminates the need for a constant power source and provides flexibility for continuous use.

3. Simple Operation: These machines are already built with a user-friendly interface. So that customers do not need any kind of training to operate this machine. This machine has to be operated like a mobile device.

4. Quick Setup and Changeover: The handy batch coding machine is designed in such a way that you can easily set it up and easily print one product after another, which will increase your productivity in less time.

5. Variable Data Printing: This machine is typically designed to print date, batch number, serial number, barcode, and other product identifier information such as logo, QR codes, etc on your product.

6. Printing Technologies: This machine prints using different types of printing technologies like inkjet printing and thermal printing. With this machine, you can print on any type of product.

7. Durable Construction: Considering the portable nature of this machine, this machine has been made using very good plastic and fiber. These batches are made from high-quality and durable materials.

8. Compatibility: This machine can print on any type of material like plastic, iron, steel marble, etc. Therefore this machine is the best machine for printing on products.

9. Affordability: Batch coding machines are usually cheaper and more economical than larger, self-powered batch coding machines. It provides cost-effective solutions for small businesses and industries.

Price Range Of Batch Coding Machine

Whether it be the brand, printing speed, or technology, several factors influence the price of batch coding in India. For Basic manual batch machines, one can expect to pay between ₹8,000 to ₹20,000, while Semi-automated models are priced between ₹25,000 to ₹60,000. When it comes to advanced automatic features, the price can greatly increase, with an industrial-grade machine ranging from ₹75,000 to ₹3,00,000. Make sure to select a machine that optimally fits your production budget and requirements.

5 Best Batch Coding Machines in India

1. Manual Batch Coding Machine

The manual batch coding machine is the most convenient and economical of all solutions for smaller to medium-sized productions. Before marking products, operators can set the desired information manually.

2. Handheld Inkjet Batch Coding Machine

The handheld inkjet batch coding machine offers excellent portability and flexibility, making it a valuable companion on the production floor. Such a machine uses inkjet technology to print on paper, plastic, and metal.

3. Ribbon Batch Coding Machine

In high-volume production settings, ribbon coding machines are particularly noted for their efficiency and reliability. They use thermal transfer technology, applying ink by a ribbon onto the packaging materials.

4. Solid Ink Batch Coding Machine

Among the many benefits of solid ink coding machines, they’re known for their high print quality and low maintenance needs. They rely on solid ink sticks which are melted and applied to the packaging material, making prints lively without any problems of variation.

5. TIJ Conveyor Batch Coding Machine

TIJ Conveyor Batch Coding Machine is custom-made and designed to operate smoothly in conveyor systems for an automatic and uninterrupted encoding solution. Thermal inkjet technology is used by these machines to print high-resolution images on a variety of materials.

Conclusion

A handy batch coding machine offers a suitable and flexible solution for small and medium-sized businesses in various industries. It provides mobility and ease of use without compromising functionality or marking quality, making it an excellent choice for those looking for an efficient and cost-effective solution. For businesses considering their options, the batch coding machine price is also highly competitive, adding further value to its practicality.

Reviews

There are no reviews yet.